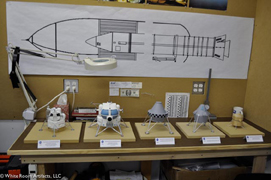

Putting the pieces together for the Shuttle, and getting it ready for the exhibit. Courtesy of White Room Artifacts.

Latest News

May 14, 2013

For the first time, Europe has had the chance to see the hardware and technology behind some of NASA’s projects. Called “NASA: A Human Adventure,” the exhibition, which launched in January 2011, has assembled a collection of instruments, artifacts, and spacecraft.

NASA’s space exploration equipment has moved from Stockholm, Sweden to Madrid, Spain, and to Istanbul, Turkey, through the space act agreement. White Room Artifacts used a variety of materials and processes, including 3D printed models produced by Solid Concepts, to manufacture the necessary pieces.

“We often get the greatest results for the money we spend by incorporating real-life models as opposed to the time, energy, and expertise it would take to provide computer animations to the shots,” said Don Bies, owner of White Room Artifacts.

Along with his work with White Room Artifacts, Bies has experience working on films at Industrial Light & Magic including such titles as Indiana Jones and the Last Crusade, the Star Wars prequels, Pirates of the Caribbean films, and Galaxy Quest.

Bies and his team use a combination of different CAD software programs, such as SolidWorks and Rhino, to provide three-dimensional drawings for additive manufacturing (AM). The CAD files are saved in the standard STL format, which is then mathematically sliced into thin layers so that stereolithography (SLA) machines can produce the model one layer at a time.

SLA uses a liquid, UV-curable photopolymer resin that is subjected to a UV laser beam. The laser, using digital data downloaded into a motion system, traces a cross-section of the part over the surface of the photopolymer. The resin hardens and bonds to the just-completed layer below it. The process is repeated continually until the machine builds the complete 3D component.

Excess resin is drained and the model placed in a UV oven for final curing. Tolerances for this AM process are +/-0.005 inch for the initial inch, and 0.0015 inch for each additional inch. Layer thickness ranges from 0.004 to 0.007 inch. SLA can produce parts quickly, with no tooling required, and the resins used in the process can somewhat mimic production plastics such as ABS, polypropylene, and polycarbonate.

One potential problem for White Room Artifacts was the size of some of the parts they needed to build. Recreating vintage spacecraft could use a lot of material, and potentially cost a lot of money to produce, as well as to ship. Much of what’s produced for the film industry is manufactured using vacuum forming. For the NASA models, such as the F1 engine, the biggest engine every built, the team felt there had to be another way, particularly considering the Apollo 11 spacecraft had five of the engines.

The model itself was to be about 36 ft. long, so the engines were often more than 21 inches high. The team decided to use Solid Concepts proprietary ID-Light technology for the larger components, and standard SLA technology for the smaller or simpler shapes they would need. The smallest SLA-built parts could be completed in 5 or 10 minutes.

ID-Light is an SLA product that is created using a proprietary laser-scanning pattern and post-processing methods. A thin outer shell (0.030 to 0.040 inch) is fabricated to encase a drainable rigid inner scaffolding-like matrix, which makes parts manufactured using ID-Light between 80 to 92% lighter than solid SLA parts (depending on geometry), according to Solid Concepts. The company says ID-Light parts also build faster than standard SLA parts.

ID-Light was originally developed by Solid Concepts to create large appearance models that were also lightweight. White Room Artifacts used the ID-Light parts for the final manufactured components.

“It’s a great material and holds sharp tolerances and accurate form,” said Bies. “Best of all, as a very lightweight material, it is inexpensive to ship from location to location during the display’s European tour.”

“NASA: A Human Adventure” is now in the early production stages for its American tour. Below you’ll find a short video about the exhibit.

Source: Terry Persun contributed this guest post on behalf of Solid Concepts. Persun is a technology journalist who has worked as an engineer as well as a marketing consultant. Seven of his novels have been published. “Cathedral of Dreams” is a ForeWord magazine Book of the Year finalist. “Revision 7:DNA” is his latest title.

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News