Carbomorph Material Expands Printed Electronics for 3D Printing

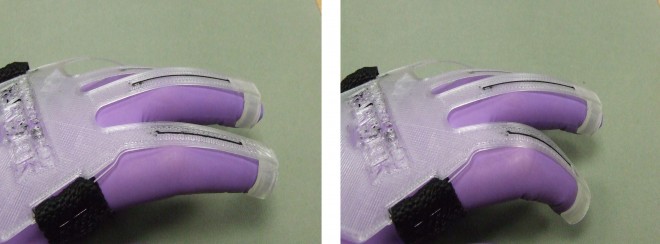

The carbomorph sensors on the glove detect the resistance generated by flexing fingers. Courtesy of University of Warwick.

Latest News

December 11, 2012

In many ways, the future of additive manufacturing (AM) is in materials. If you don’t have suitable materials for the task at hand, it doesn’t matter how large a build envelope manufacturers can develop, or how quickly objects can be built. Objet (now Stratasys) is a good example of a company that understands this, with its large catalog of materials.

That’s not to say plastic and the various metals aren’t good for what they do, but those materials can’t do everything. As we’ve covered before, printed electronics go with 3D printing like peanut butter goes with jelly. It’s only natural, then, that someone would come up with an AM material that is electrically conductive.

Researchers at the University of Warwick have come up with a material they are calling “carbomorph” that is designed to be used in 3D printers. The team made the material by combining carbon black filler with polymorph modeling plastic, which is a commercial version of polycaprolactone (PCL). According to the research team, the result can be run through any 3D printer that uses a material extrusion process (such as Stratasys’ fused deposition modeling).

PCL is biodegradable and has a low melting point, which makes it ideal for AM. Objects built using carbomorph look identical to plastic parts, and have the added bonus of being conductive.

“We got a bit frustrated by seeing nice 3D printed objects that didn’t actually do a lot,” said team leader, Dr. Simon Leigh.

This kind of breakthrough is pretty amazing on its own, but it’s also intended to be easy enough to reproduce for anyone with the right ingredients and a material extrusion 3D printer. Leigh and his colleagues have released their findings in a paper named “A Simple, Low-Cost Conductive Composite Material for 3D Printing of Electronic Sensors” published in the open-access, online journal PLOS One.

“One of the goals of the project was to try and develop a material that was as simple as possible to make so that a hobbyist could produce it if they wanted,” said Leigh. “It’s the idea of empowering people by giving them the tools to decide how they interact with the technology around them.”

The research team has tested carbomorph by printing out a game controller, flex sensors in a glove, and heat sensors in a coffee mug. Creative individuals and businesses will, no doubt, come up with many other potential applications for the new material. For those without a lab, Leigh and his colleagues are investigating methods of providing carbomorph for sale.

Below you’ll find a video that discusses the potential of printed electronics.

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE