Rapid Ready Roundup: Short-pulse Lasers, Cube Garners Award, SLM North America and Burritos

The Burritob0t. Culinary extravaganza. Courtesy of Marko Manriquez.

Latest News

June 21, 2012

In the course of my diligent efforts to keep you good people up to date on the state of additive manufacturing, I come across many interesting news items. I’ll gather them up every so often and present them in a Rapid Ready Roundup (like this one). You can find the last Roundup here.

We’ll begin in Aachen, Germany, where the International Laser Technology Congress (AKL) was held in early May. The main star of the show was breakthroughs in the use of ultrashort pulse lasers (USP).

Potential uses for the technology in additive manufacturing (AM) have increased, thanks to the emergence of systems with an output in excess of 100 Watts. Not only have USPs made inroads to AM, but also with 3D scanning. New scanner tech using USP has been developed that scan speeds of up to 50 m/s.

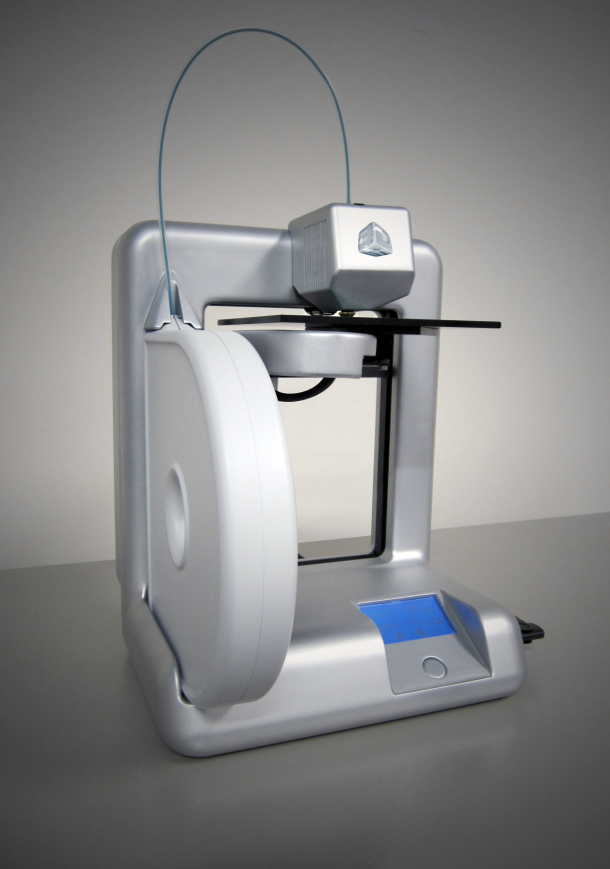

3D Systems’ Cube has received the American Technology Award (ATA) for outstanding achievement in Technology Manufacturing. The award was presented at a ceremony inWashington, D.C. A panel of industry and technology experts determined the winner, based on products and services that have furthered technology in some manner.

“We are deeply honored to have been selected for this prestigious award. Cube began shipping to consumers just two weeks ago and we are delighted with the overwhelming response to this exciting ‘plug and play’ 3D printer for the home,” said Abe Reichental, president and CEO of 3D Systems.

Moving on, SLM Solutions has opened up a North American office in Commerce, MI. The NA office will offer the full range of SLM services, with a focus on AM.

“We can provide a number of solutions to our customers, from building prototype parts with one of our three standard machine offerings, with any of our 10 metal materials; to adding various options like closed loop material handling and process monitoring for series production of consistent metal parts, or even helping our customer create a special process with custom designed capabilities,” said Jim Fendrick vice president of SLM Solutions NA Inc.

Finally, just when you think you’ve seen it all, something new comes along. While I have covered 3D printers that build food before, this is much, much different. The Burritob0t was created by Marko Manriquez for his graduate thesis project. Manriquez attended the Tisch School of the Arts, which is part of NYU.

Basing the project on the open source RepRap design, Manriquez added multiple extruders (basically large hypodermic needles with the actual needle removed) filled with ingredients like beans, sour cream and cheese. The extruders are controlled by an app created by Manriquez for the iPad or iPhone, and rotate to ooze whichever material is desired to build the next layer of the culinary delight.

Below you’ll find a video about the Burritob0t because, really, how could I resist sharing.

Sources: Industrial Laser Solutions, SLM Solutions, MarketWatch, PC World

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE