Stratasys and Optomec Combine 3D Printing and Printed Electronics

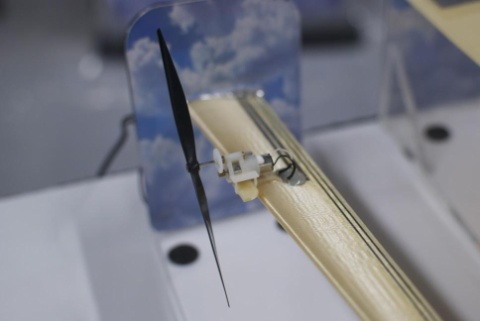

An aerosol jet prints circuitry on a wing built using FDM. Courtesy of Stratasys and Optomec.

Latest News

March 27, 2012

As much as we love 3D printing, we realize other rapid technologies are advancing in exciting ways. Printed electronics, particularly printed circuit boards (PCB) is one such area that could bring improvements to consumers in everything from smart phones to RFID-like clothing. With that in mind, it’s particularly exciting to discover a new combination of both 3D printing and printed electronics.

Stratasys and Optomec have combined resources to create a way to incorporate printed electronics into additive manufacturing (AM). This hybrid approach builds an object that isn’t required to have holes for wires or slots for chips. It is pure form follows function.

The first prototype created with the new process is what the companies are calling a “smart wing” for an unmanned aerial vehicle (UAV). The wing has functional electronics built into the design, a process that could also be used in the medical device, consumer electronics and automotive industries. The all-in-one approach this brings can reduce the overall weight of parts, as well as enhance them with ingrained technology.

Bringing together 3D printing and printed electronic circuitry will be a game changer for design and manufacturing. It has the potential to completely streamline production by requiring fewer materials and steps to bring a product to market. –Jeff DeGrange, vice president of direct digital manufacturing at Stratasys

The hybrid process used an Optomec Aerosol Jet system to print a conformal sensor, antenna and circuitry directly onto the wing of a UAV model that was built by Stratasys. Electrical and sensor designs were provided by Aurora Flight Sciences.

“The ability to fabricate functional electronics into complex-shaped structures using additive manufacturing can allow UAVs to be built more quickly, with more customization, potentially closer to the field where they’re needed,” added David Kordonowy, Aurora Flight Sciences’ aerostructures research group. “All these benefits can lead to efficient, cost-effective fielded vehicles.”

Below you’ll find a short video about the hybrid process.

Source: Stratasys

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE