MIT Prints Shape-Shifting Soft ‘Bots

Latest News

June 26, 2018

Researchers in a variety of fields have been working on creating different types of structures and robots that can move or restructure themselves based on external inputs, including everything from shape-shifting nanotechnology to giant art pieces that use wind power to move about on their own. MIT engineers have joined the fray with 3D-printed structures that can change shape and move using magnetism.

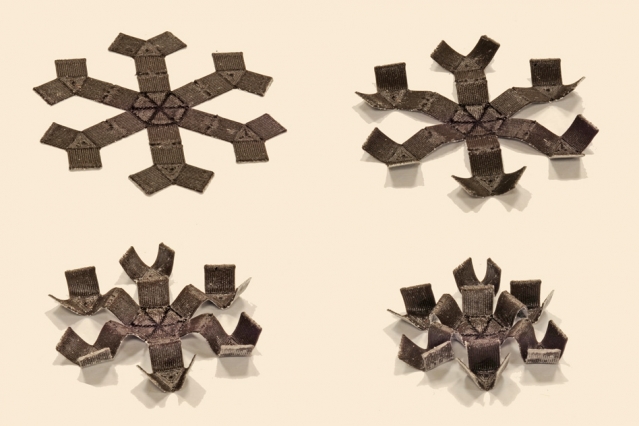

Image courtesy of MIT.

Image courtesy of MIT.The soft structures are printed from a special ink infused with tiny magnetic particles. Using an electromagnet fitted on the nozzle of a 3D printer, the researchers can orient the particles during the print process, controlling that orientation in individual sections of the final structure.

The printed structures can then be shifted into different formations or move in response to an external magnetic field. So far, the team has created a smooth ring that can wrinkle itself up, a long tube that can squeeze shut, a sheet that folds itself, and a grabber that can crawl, roll, or snap together to catch a passing ball. The device can also hold and carry a small pill. The team also created a physical model to predict how the structures would perform under a magnetic field.

The technology could be used to create magnetically controlled biomedical devices.

“We think in biomedicine this technique will find promising applications,” said Xuanhe Zhao, Noyce Career Development Professor in MIT’s Department of Mechanical Engineering and Department of Civil and Environmental Engineering. “For example, we could put a structure around a blood vessel to control the pumping of blood, or use a magnet to guide a device through the GI (gastrointestinal) tract to take images, extract tissue samples, clear a blockage, or deliver certain drugs to a specific location. You can design, simulate, and then just print to achieve various functions.”

There are other types of soft actuated devices that are created using hydrogel, shape-memory polymers, and liquid crystal elastomers, but these materials are often slow to respond. Using 3D-printed magnetic materials can allow these “soft robots” to perform tasks much more quickly. Magnetism also allows for the robots to complete more complicated tasks.

“There is no ideal candidate for a soft robot that can perform in an enclosed space like a human body, where you’d want to carry out certain tasks untethered,” said researcher Yoonho Kim. “That’s why we think there’s great promise in this idea of magnetic actuation, because it is fast, forceful, body-benign, and can be remotely controlled.”

You can read more about the project in the journal Nature, or watch the video below.

Source: MIT”

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

Brian Albright is the editorial director of Digital Engineering. Contact him at [email protected].

Follow DE