MIT Foundry Simplifies Multi-Material Design

Latest News

November 14, 2016

Creating objects out of multiple materials is a complex process that traditionally involves dividing the object into separate components, fabricating them, and then bonding them together after the fact. That’s also the case in most current 3D printing operations.

Using Foundry, MIT researchers designed and fabricated skis with retro-reflective surfaces, a ping-pong paddle, a helmet, and a bone. Image: MIT News

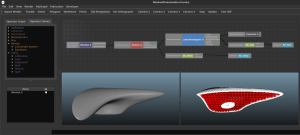

Using Foundry, MIT researchers designed and fabricated skis with retro-reflective surfaces, a ping-pong paddle, a helmet, and a bone. Image: MIT NewsMIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) has come up with a way to design objects out of multiple or mixed materials, and the system is so simple to use that even novices can quickly create such designs.

CSAIL unveiled the new solution, called Foundry, back in October. The project was supported by the National Science Foundation.

“In traditional manufacturing, objects made of different materials are manufactured via separate processes and then assembled with an adhesive or another binding process,” said PhD student Kiril Vidimče, the first author on the paper. “Even existing multi-material 3D printers have a similar workflow: parts are designed in traditional CAD systems one at a time and then the print software allows the user to assign a single material to each part.”

What Foundry does is provide an easy-to-use interface so that designers can vary material properties at a very fine resolution. This makes it possible to design with multiple materials or mixtures of materials.

And users can do so without complex programming. “It’s like Photoshop for 3D materials, allowing you to design objects made of new composite materials that have the optimal mechanical, thermal, and conductive properties that you need for a given task,” Vidimče said. “You are only constrained by your creativity and your ideas on how to combine materials in novel ways.”

And users can do so without complex programming. “It’s like Photoshop for 3D materials, allowing you to design objects made of new composite materials that have the optimal mechanical, thermal, and conductive properties that you need for a given task,” Vidimče said. “You are only constrained by your creativity and your ideas on how to combine materials in novel ways.”

Users can design an object in a CAD program, then export it into Foundry. Designers can then determine the object’s composition using roughly 100 fine-tuned actions (referred to as operators). Those operators can then remap and assign materials in the object.

The solution is so easy to use that MIT tested it with non-designers. With just an hour’s worth of instruction, the test group was able to design a teddy bear, a bone structure and an integrated tire/wheel. Most of the test group were able to create workable designs in less than an hour.

Source: MIT News

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

Brian Albright is the editorial director of Digital Engineering. Contact him at [email protected].

Follow DERelated Topics