UC Berkeley Develops 3D Printed Sensors for Food Safety

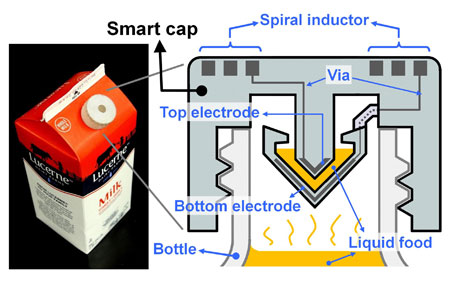

UC Berkeley engineers created a ‘smart cap’ using 3D-printed plastic with embedded electronics to wirelessly monitor the freshness of milk. Courtesy of Sung-Yueh Wu.

Latest News

July 20, 2015

Researchers and makers around the world have discovered many, many different ways to put additive manufacturing (AM) to good use. Regardless of how much potential it seems like a new technology has, if no one can figure out a way to leverage that potential for practical purposes, it might as well not exist.

Researchers at UC Berkeley in cooperation with Taiwan’s National Chiao Tung University have been hard at work developing practical applications for 3D printed electronic circuits and wireless sensors. The result of the team’s first foray into this area of applications is a smart cap, produced by AM, which is capable of reporting the freshness of milk.

UC Berkeley engineers created a ‘smart cap’ using 3D-printed plastic with embedded electronics to wirelessly monitor the freshness of milk. Courtesy of Sung-Yueh Wu.

UC Berkeley engineers created a ‘smart cap’ using 3D-printed plastic with embedded electronics to wirelessly monitor the freshness of milk. Courtesy of Sung-Yueh Wu.While that may not seem very exciting at first glance, consider applying the same technology to a broader amount of food. Consumers could guarantee food safety and freshness simply by scanning the output of a smart label with a phone.

“This 3D-printing technology could eventually make electronic circuits cheap enough to be added to packaging to provide food safety alerts for consumers,” said senior author Liwei Lin, a professor of mechanical engineering and co-director of the Berkeley Sensor and Actuator Center. “You could imagine a scenario where you can use your cellphone to check the freshness of food while it’s still on the store shelves.”

The same idea could be put to monitoring other, more hazardous materials as well. That scenario would result in safer working conditions for the people assigned to monitor those same hazardous materials. Rather than opening a container or withdrawing a sample that could be spilled, workers could just scan sensors already at work inside the container.

Researchers built the smart cap through what amounts to lost wax casting. A part was printed using wax and polymers, with the wax being removed after printing was completed. The research team then filled the empty spaces within the parts with silver, which was left to cure. The end result was a series of electrical components.

Full details of the research team’s work were published in the online journal Microsystems and Nanoengineering under the title “3D-printed microelectronics for integrated circuitry and passive wireless sensors.”

Below you’ll find a video discussing food freshness to hold you over until those smart labels show up.

Source: UC Berkeley

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE