3D Printed Functional Polymers Reveal Material Stress

Production of plastic objects including stress indicators. Courtesy of the University of Washington.

Latest News

February 11, 2015

As with any manufacturing process, additive manufacturing (AM) is only as good as its materials. In some ways, AM is already ahead of the curve when discussing materials, simply because so little material is wasted during a build. The last several years have also seen an increase in materials designed specifically for AM, rather than materials that were adapted to 3D printing.

Another advantage of AM is that item production can sometimes be halted and restarted. This allows for a certain amount of object customization that isn’t as easy with traditional manufacturing processes. Researchers at the University of Washington (UW) are taking advantage of this aspect of 3D printing to develop functional polymers.

Production of 3D printed plastic objects including stress indicators. Courtesy of the University of Washington.

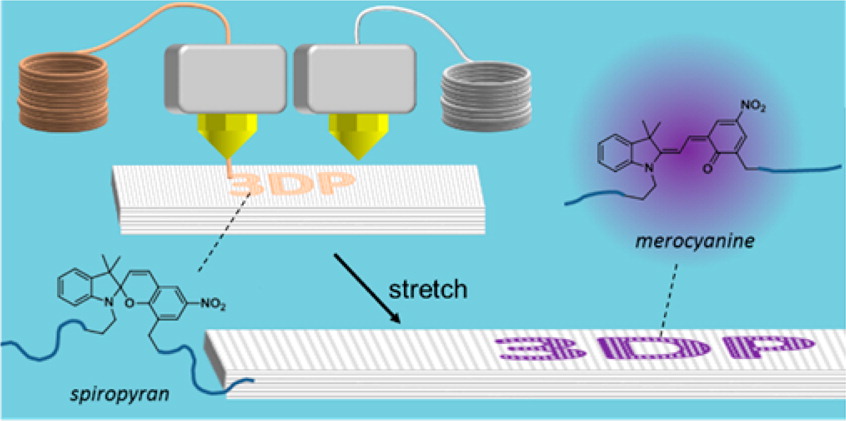

Production of 3D printed plastic objects including stress indicators. Courtesy of the University of Washington.Functional polymers react to outside influences, such as heat, light, or stress, in a number of different ways, including by changing shape or color. The changes the material undergoes acts as a passive mechanical sensor that is capable of alerting onlookers to changes in material stress. It can be challenging to integrate functional polymers into objects produced through traditional manufacturing because the heat and pressure typical for many processes would cause the functional polymer to indicate prematurely.

AM works at much lower temperatures than other manufacturing processes, making it a likely candidate for generating functional polymer objects. UW doctoral students, Gregory Peterson and Michael Larsen, fed two polymers into a dual-extruder system. One extruder contained polycaprolactone and the other extruder a mixture of the same material and a molecule named spiropyran, which responds to stress by changing color.

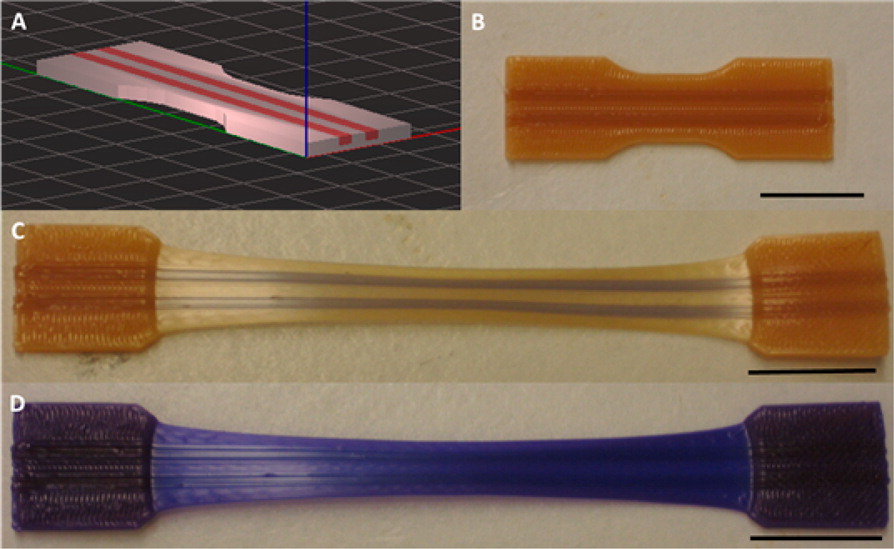

The majority of the test object, a dog bone shaped plastic object, was built using the polycaprolactone alone, but the university initials (UW) incorporated into the center of the object contained the spiropyran mix. The end result was that when the object was stretched, the UW turned color from yellow to purple, indicating that object had been subjected to stress.

The before and after results show how the color of the plastic changes with stress. Courtesy of the University of Washington.

The before and after results show how the color of the plastic changes with stress. Courtesy of the University of Washington.A second experiment inserted four smaller tabs of the spiropyran mix inside a plastic strip. As the strip was stretched, each tab would change color, displaying the amount of stress in stages.

“We wanted to demonstrate that the functional chemistry could be incorporated readily into already printable materials,” said Andrew J. Boydston, a UW assistant professor of chemistry. “We found that designer chemistry can be incorporated into 3-D printing very rapidly.”

The research could lead to a number of practical applications, such as plastic surfaces that turn color as a result of being struck hard enough to weaken the material, or just giving some warning to users than an object might be about to break as the result of too much stress. The team published a paper named “3D-Printed Mechanochromic Materials” documenting its findings in the American Chemical Society’s journal of Applied Materials and Interfaces.

Below you’ll find a video that discusses functional materials.

Sources: University of Washington, Scientific America, ACS Applied Materials and Interfaces

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE