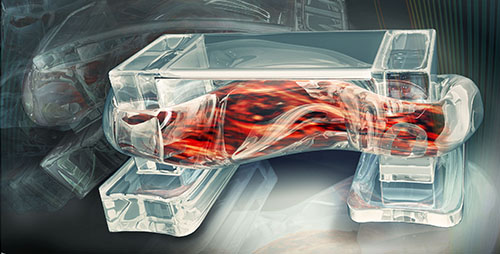

The musculature” that allows the bio-bot to walk was built thanks to 3D printing. Courtesy of U of I.”

Latest News

July 3, 2014

Mechanical devices with a biological structure have been standard fare in science fiction for at least 100 years. Often, these sorts of devices are used to stress the “otherness” of aliens, travelers from alternate dimension, or even stranger sorts of creatures. Even if a machine is fantastically complex, it still looks like a machine. A machine with flesh, blood-like fluids, and muscles is something altogether different.

Real world scientists have long studied biology for inspiration – a process called biomimicry – but only a small amount of actual biological-mechanical hybrids have yet to become a reality. Researchers at the University of Illinois at Urbana-Champaign (U of I) have taken a step forward in biomechanical fabrication with the construction of muscle-powered bio-bots which are capable of movement when stimulated by electric pulses.

The “musculature” that allows the bio-bot to walk was built thanks to 3D printing. Courtesy of U of I.

The “musculature” that allows the bio-bot to walk was built thanks to 3D printing. Courtesy of U of I.“Biological actuation driven by cells is a fundamental need for any kind of biological machine you want to build,” said study leader Rashid Bashir, Abel Bliss Professor and head of bioengineering at the U. of I. “We’re trying to integrate these principles of engineering with biology in a way that can be used to design and develop biological machines and systems for environmental and medical applications. Biology is tremendously powerful, and if we can somehow learn to harness its advantages for useful applications, it could bring about a lot of great things.”

Previous bio-bots were built using heart cells from rats, but while the constant beating of the cells made the bots ambulatory, it also made it difficult to direct the bio-bots. The new bio-bots are less than inch large and were built using a combination of pre-fabricated posts (that also act as feet), a backbone of 3D printed hydrogel, and living skeletal muscle cells.

The new design mimics the muscle-tendon-bone complex found in nature, and can be turned on by exposure to electric pulses. Researchers can even control the speed of the bio-bots by increasing or decreasing the frequency of the pulses. The next step is to add neurons to the bio-bots so they can be steered in specific directions using light of chemical gradients.

Bashir credits 3D printing as one reason why research has progressed. The ability to quickly produce new models to test new theories wouldn’t have been possible prior to the adoption of the new technology. According to the research team, the first application for the bio-bots will be as autonomous sensors that will react to the presence of dangerous chemicals by advancing toward the problem and releasing a counter-agent.

Below you’ll find a video about the bio-bots.

Source: I of U

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE