RAPID 2014 Comes of Age in Detroit

Latest News

June 13, 2014

While introducing a keynote speaker at RAPID 2014, SME President Michael F. Molnar joked that, after 21 years, the rapid prototyping and manufacturing event was finally old enough to buy a drink. It was an appropriate analogy as one of the event’s biggest segments, 3D printing, has matured to the point of being accepted by many of the companies that attended The Big M, a manufacturing conference co-located with RAPID 2014 for the first time this year in Detroit.

In fact, the RAPID side of the exhibition hall was noticeably more crowded than The Big M side, as attendees crowded booths filled with 3D printers, 3D scanners, metrology equipment, computer-aided manufacturing machines, as well as materials and software.

“The caliber of company names on the badges of people visiting our booth has been really impressive this year,” said David Burns, president and chief operating officer of ExOne. He said big industry is now showing a keen interest in additive manufacturing.

Manufacturing Muscle

The Big M co-location and the Detroit venue may have contributed to the spirit of the event. Many of the presentations and announcements at RAPID 2014 focused on the role advanced manufacturing have to play in boosting the profile of manufacturing in America.

U.S. Secretary of Commerce Penny Pritzker greets students from one of

U.S. Secretary of Commerce Penny Pritzker greets students from one ofSME’s PRIME schools. She kicked off SME’s THE BIG M event as the keynote speaker and introduced the SME and 3D Systems M.Lab21 initiative.

For example, during the opening keynote, U.S. Secretary of Commerce Penny Pritzker announced the M.Lab21 initiative between SME and 3D Systems to enhance high school industrial arts and vocational education classes. The program will offer starter kits intended to transform shop classes and incorporate additive manufacturing into curriculums.

“We need the public and private sectors to work together now more than ever to focus our investments on areas with the highest potential for growth,” said Secretary Pritzker. “Our objective (at the Whitehouse Office of Manufacturing Policy) is to break down the silos across the government and encourage meaningful public-private partnerships at every level to move American manufacturing forward.”

Talking Trends

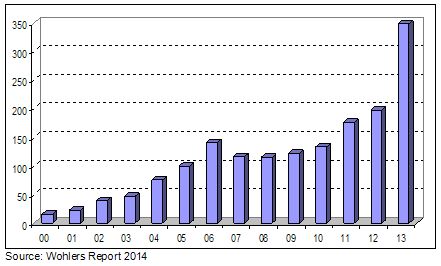

Terry Wohlers’ data seemed to support the hypothesis that industry has latched onto 3D printing. Wohlers is principal consultant and president of Wohlers Associates, which produces an annual report on the state of the additive manufacturing industry.

He opened the final day of the conference by pointing out trends he has seen over the past year. According to the 2014 Wohlers Report, sales of 3D printers capable of producing metal parts increased almost 76% vs. 2012. Such machines are not widely used by hobbyists. That growth is primarily coming from the medical, dental and aerospace industries.

Metal based AM machine unit sales by year. In 2013, 348 such machines were sold. Source: Wohlers Associates, Inc.

Metal based AM machine unit sales by year. In 2013, 348 such machines were sold. Source: Wohlers Associates, Inc.In the past, materials were sometimes blamed for the seemingly slow uptake of 3D printing by industry when compared to the consumer 3D printer hype, but many RAPID 2014 exhibitors had material solutions on display:

- Stratasys officially launched three new flexible 72-color palettes, composed of its rubber-like (TangoPlus) material and combinations of rigid opaque (VeroCyan, VeroMagenta and VeroYellow) materials, as well as three flexible 68-color palettes, built with rubber-like (TangoBlackPlus) and combinations of the same rigid opaque (Vero) colors. The new palettes are extensions to its range of flexible and rigid material options for the Objet500 Connex3 Color Multi-material 3D Printer. Read more here.

- ExOne had its new Inconel alloy 625 on hand in its booth. The nickel-based alloy is the first single metal alloy for 3D printing industrial applications to achieve more than 99% density using its binder jetting technology, according to the company. The ExOne Material Applications Laboratory qualified the material for ExOne’s M-Flex and X1-Lab 3D printers.

- Mcor, known for using paper as the raw material for its 3D printers, announced FLEX, a finishing option for users of the company’s IRIS and Matrix 3D printers that allows them to produce pliable models that are water resistant.

- Fenner Drives’ new NinjaFlex materials received rave reviews from open-source, fused-deposition-based 3D printer manufacturers on the show floor. The thermoplastic elastomer has high elasticity, giving users another option for flexible prints.

- Autodesk is also looking to material innovation as part of its entry into the 3D printing market. (See previous coverage here.) As part of its open source initiative, the company says it will share some of its research so third parties can create materials that will work on its 3D printers.

A tour of ExOne’s nearby facility in Troy, MI, revealed the company is beta testing a ceramic material for use in its additive manufacturing machines that dispense layers of resins into specially engineered sands or powders. Representatives of the company explained how they take customer design files, prepare them for 3D printing, perform quality checks on the physical products and ship them out.

ExOne uses a @FARO_HQ Arm scanner in its quality control room for inspection and reverse engineering. #RAPID2014 pic.twitter.com/Y0VXjbvXWw— Desktop Engineering (@DEeditor) June 10, 2014

New Hardware

Materials weren’t the only announcements being made at RAPID 2014. Many new 3D printers were on display.- EOS showed off its EOS M 290 system, which the company says is designed for the tool-free production of high-quality serial components, spare parts and prototypes. It features a build volume of 9.84 x 9.84 x 12.79 in., monitoring functions for the system and the build process, and a 400-Watt laser.

- Formlabs announced its Form 1+ desktop stereolithographic 3D printer. The company says its second-generation laser system is four times more powerful than its predecessor, allowing it to print up to 50% faster.

- Prodways presented its product lineup of MOVINGLight Technology 3D printing manufacturing systems for the first time in the US. The French company also announced its first North American distributor, GENISTAR.

- 3DP Unlimited had its 3.28 x 3.28 x 1.64 ft., open source, fused filament fabrication 3DP1000 printer running in its booth. The company is a division of PBC Linear, which has its roots in motion control. Its lineage helped it create a smooth, screw-driven system that can print up to 70 microns in resolution.

@3DPUnlimited is demonstrating its large-format 3D printer. It’s open source and starts at <$16,000. #RAPID2014 pic.twitter.com/RIDAN9PtKw— Desktop Engineering (@DEeditor) June 11, 2014

RoboCop suit and helmet designed and produced by Legacy Effects using Stratasys Objet Connex multi-material 3D printing.

RoboCop suit and helmet designed and produced by Legacy Effects using Stratasys Objet Connex multi-material 3D printing.3D Printing Goes Hollywood

RAPID 2014 had host of impressive speakers, but none were more entertaining than Jason Lopes, lead systems engineer for Legacy Effects. The special effects company has worked on movies such as Iron Man 3, Pacific Rim, Hunger Games, this year’s RoboCop remake and more. Lopes began using 3D printing in 2006 when it helped Legacy Effects land a. The business took off from there, and now Legacy Effects owns seven 3D printers, including three from Stratays, as well as a Makerbot (owned by Stratasys) Replicator 2, an EnvisionTEC Perfactory 3 and an Ultimaker 2. But that’s not enough. “While (rapid prototyping service providers) Cideas and Solid Concepts are building big stuff for us, we use our Connex500 3D printer for the fun stuff,” he told the RAPID 2014 crowd. The video below, produced by Stratasys, features Lopes explaining how 3D printing is integral to Legacy Effects’ design process.

For more coverage of RAPID 2014, see Desktop Engineering’s Twitter feed for an archive of our live tweets from the show, as well as our previous coverage here on Rapid Ready Technology. Below is an album of RAPID 2014 images posted on Desktop Engineering’s Facebook page.

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

Jamie Gooch is the former editorial director of Digital Engineering.

Follow DE