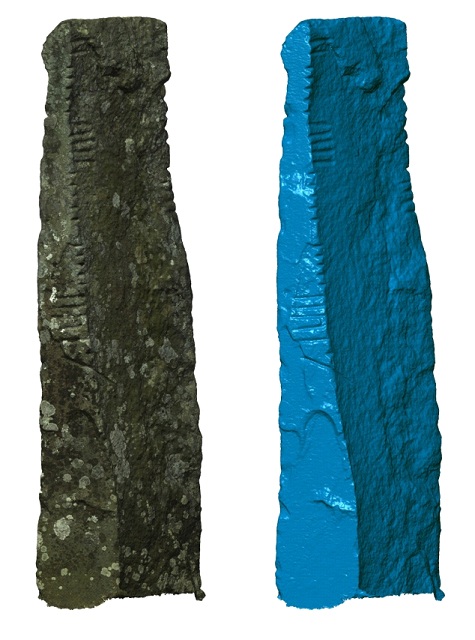

Here you can see the original image of the Ogham alongside its 3D scanned counterpart. Courtesy of Artec.

Latest News

December 19, 2013

The earliest examples of written language in Ireland can still be found dotting the island. Hundreds of Ogham stones record Irish history, their carvings preserving names of important individuals, tribal affiliation, or geographical information. The oldest of the stones can be traced back to the 4th century CE and vary in shape and size, with the average stone standing at around 5 ft. tall.

Ogham stones are an Irish national treasure, and provide information of interest to historians, linguists and archaeologists. Situated above ground, time and the elements are slowing scrubbing the stones of the distinctive system of notches and horizontal or diagonal lines/scores that represent an early Irish language. In an effort to preserve the history represented by the stones, researchers from Dublin Institute of Advanced Studies (Dias) have begun a project to digitize them using an Artec Eva scanner.

“The importance of Ogham stones cannot be overstated as they are a record of the earliest inscriptions in the Irish language,” said Jimmy Deenihan, Minister for Arts, Heritage and the Gaeltacht. “Some of them date as far back as the 4th Century AD, and represent a monument type that is not only of national, but also international significance. This wonderful project demonstrates the importance of developing synergies with institutions. Such cooperation not only maintains advances in research and contributes to promoting awareness of the rich archaeological heritage of the country but it also further enhances its protection.”

More than 50 stones have been digitally captured. The 3D images are stored in Dias’ digital archives, and are available for study or view to anyone with an internet connection at the Institute’s Ogham in 3D website. Not only does 3D scanning the Ogham ensure the survival of the information carved into the stones, computers can use various filters and other digital enhancements to reveal details that may have become obscured on the original stone.

The scanning work is undertaken with the fastest speed setting and with a minimum 400 mm depth of field. The data is recorded with overlap between scans to ensure easy registration. Post-processing is done in Artec Studio 9 software, where individual scans are edited and aligned, before a final surface is generated using global registration, fusion, and a small objects filter algorithm. A textured surface can also be created, if required, in order to ensure every detail has been represented. To complete the project, a model is exported from Artec Studio 9 as an .obj file.

Below you’ll find a video about the project.

Sources: Artec, Ogham in 3D, Dias

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE