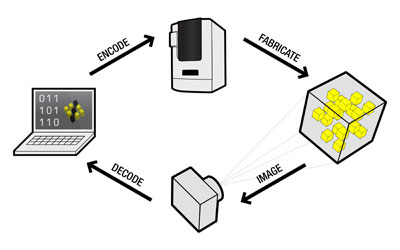

A computer generated 3D code is built in a 3D printer as part of an object, which can then be read using THz scanning to reveal the information stored within. Courtesy of Microsoft.

Latest News

September 17, 2013

Hang around the technology crowd for long enough and you’ll probably hear murmurs about the Internet of Things (IoT). For those who aren’t aware, the IoT is a concept slowly coming to fruition in which everyday objects — the door to your fridge, your running shoes — are connected to Wi-Fi via sensors embedded within or slapped on them. The sensors gather information about your activities to provide useful user feedback about how many miles you’ve run this week and how many times you’ve opened the fridge to stare forlornly inside.

Microsoft Research is just as interested in the IoT as other tech companies, and has been quietly working away on ways to include the technology in a number of objects via a variety of different sensor types. Most of this research uses RFID chips for tracking purposes, but new research has developed a method of using terahertz (THz) imaging to read specially designed structures within objects built with additive manufacturing (AM).

The system is called InfraStructs, and is the brainchild of Karl Willis, from Carnegie Mellon University, and Andrew Wilson, from Microsoft. The basic premise of InfraStructs is to use the capability of AM to build complex internal geometries to self-embed three dimensional codes into objects that have been wholly or partially built using a 3D printer. These codes are then read by a THz scanning device and used for everything from simple identification to actual programming code that allows objects to connect with outside systems.

“It has to do with the waveforms you get when the scan penetrates the object,” Wilson explains. “We are able to distinguish between transitions in the material, void or non-void, by measuring the reflection distance. We investigated a lot of the really early depth-camera technologies, and at some level, it’s all consistent with that line of research.”

The researchers foresee a day when InfraStructs could also be used to generate entire interactive environments for robots. Small InfraStructs codes would, fairly cheaply, allow a robot to determine what was around it and decide how to interact with its environment to complete tasks. THz technology is a bit behind other sensor research, but interest drives research, and if InfraStructs works as well as Wilson and Willis expect, it could quickly gain ground.

You can read about the research here (.pdf) and below you’ll find a video that discuss the InfraStructs system.

Source: Microsoft Research

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE