Latest News

August 16, 2013

3D printing with the ProJet HD 3000Plus helps Buttercup the duck get a new foot.

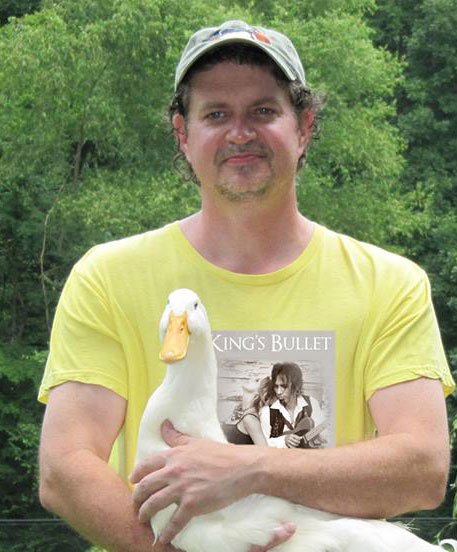

Editor’s Note: We told you briefly about how a duck became a bit of a celebrity after receiving a 3D-printed prosthetic foot, but now guest author Jacqueline Troutman of 3D Systems brings you the whole story.If you had asked Mike Garey a year ago if he ever thought he would be getting calls from Australia asking for help with injured animals, he probably would have laughed politely and looked a bit confused. Yet that’s exactly what has been happening. A Tennessee-based software engineer, Mike Garey recently and unwittingly stepped into the international animal-lovers’ spotlight for fashioning a prosthetic duck foot using 3D printing technology, a big heart, and the curiosity to see what was possible. He has since received an influx of interest from media, pet-owners, and animal specialists worldwide, asking for his attention and help with animals from dingoes to ferrets, and everything in between.

Garey and his wife had not intended to own and operate a waterfowl sanctuary, but when the geese they bought for their pond never flew away, they realized not only that the birds were there to stay, but that there were many more birds in their community that needed a good home. Traditional animal shelters cared for dogs and cats, but domestic birds (birds that cannot fly) had no place to go. Feeling an ability and obligation to fill that gap, the Gareys decided to convert their four acres into a rescue reserve for domestic ducks and geese. The Gareys now have 27 birds at Feathered Angels Waterfowl Sanctuary that they tend to with proper veterinary care, food, and safety. And now, evidently, with custom-fit prosthetics.

Buttercup Comes Hone to Roost

In January 2013, a local high school student contacted Garey in search of a home for Buttercup, a domestic duck she had inherited from a high school science class. Buttercup was born with a malformed foot, and for two and a half months the student had hand-raised him, but was no longer able to. Garey agreed to take in the duck, but quickly realized two things. First, that Buttercup did not know he was a duck due to his lack of feathered socialization; and second, that Buttercup was unable to effectively socialize because his foot caused him extreme discomfort in the yard.

With Buttercup’s first steps in front of Garey, Buttercup’s malformed foot started to bleed. Garey wondered if preserving the foot made sense, so he consulted a veterinarian and confirmed that amputating would improve Buttercup’s mobility. “I’d seen plenty of birds get around well on a peg leg, but as I started to think about it, I wondered if it would help Buttercup’s sociability if he had a foot,” Garey said. “These birds are so smart and have such great personalities, so I thought that if it were in my power to improve Buttercup’s quality of life, I should do that.” Garey liked the idea of 3D printing because it seemed like the perfect answer to the question of how to fashion a precise, custom part to his exact specifications without trading time for complexity, or vice versa.

Garey started researching his available options for 3D file creation and 3D printing, and came across NovaCopy, a Tennessee supplier of 3D printers and 3D printing solutions. The compassion and positivity of Garey’s aim immediately compelled NovaCopy to agree to help with printing. If Garey could provide a 3D file, NovaCopy could run it through one of their machines, no problem.

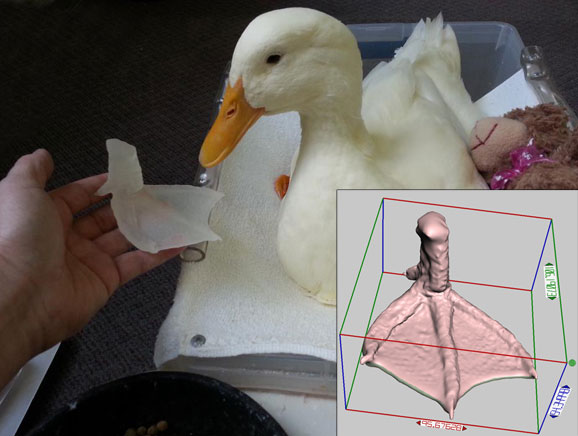

By taking multiple pictures of another duck’s foot from all angles, Gary used 3D imaging software to create a 3D model. Then, with CAD software and NovaCopy’s feedback, Garey tweaked and modified the data into a prosthetic foot design. Garey sent off the final design for NovaCopy to print, and NovaCopy selected one of its 3D Systems machines for the task – the ProJet HD 3000Plus – due to the machine’s high-resolution capabilities.

“Our ProJet HD 3000Plus consistently gives us outstanding quality prints, so it was a no-brainer to use it for a fine-detail part like this,” said Joel Graves, the 3D printing engineer who handled printing Buttercup’s prototype. Once printed, NovaCopy mailed the prototype to Garey, who used the replica to make a mold for the final silicone-casting of Buttercup’s prosthetic.

Garey made the prosthetic in two pieces that pin together at the ankle: a silicone sock to protect Buttercup’s peg and a boot to fit it. Buttercup received the prosthetic well, and started walking on it and strengthening his underused leg shortly after being outfitted.

Buttercup’s Celebrity Status Takes Off

Garey documented his and Buttercup’s progress throughout the various stages of the undertaking and has shared the process with the world through his Facebook page, “Buttercup Gets A New High Tech Foot.” Since receiving his foot, Buttercup has become a celebrity in the world of science and animal prosthetics, and in addition to being featured in online and print media, Buttercup was honored by marching with the Peabody ducks at the Peabody Hotel in Memphis, TN. As an honorary Peabody duck, Buttercup now shares a token of the celebrity of other honorary participants, such as Oprah Winfrey, Larry King and Kevin Bacon, who have each acted as honorary Duckmasters in the past.

When Garey first set out to make the prosthetic, his two main goals were to see if he could achieve what he had set out to do, and to test Buttercup’s reception. Because Buttercup accepted his new foot and Garey’s first design succeeded, Garey now wants to try designing a new foot, this time with hinged parts and a moving web. His coming iterations will give him a chance to test 3D printing technology more completely, and to streamline his process in a way that is more efficient with his time. Garey will no doubt find a way to put this new time to use, especially considering the incredible incoming of outreach he has experienced. With an empowering 3D printing experience under his belt, Garey said, “Anything I can dream up: that’s what’s next.”

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News