Rapid Ready Roundup: Music, Cube Odyssey, AMF and RedEye

Latest News

March 19, 2012

In the course of my diligent efforts to keep you good people up to date on the state of additive manufacturing, I come across many interesting news items. I’ll gather them up once every few weeks and present them in a Rapid Ready Roundup (like this one). You can find the last Roundup here.

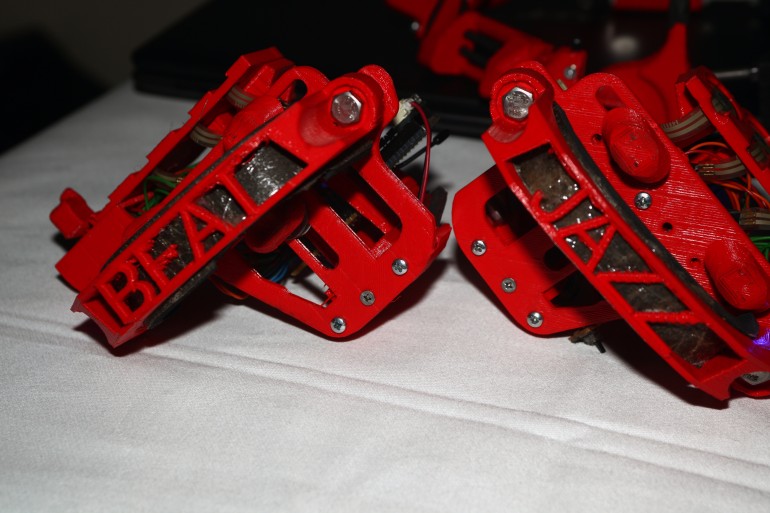

Let’s start this Roundup with a little bit of music. Musician and inventor Onyx Ashanti has created a wireless system he calls Beatjazz that allows him to create music using gestures, rather than picking out beats on a computer. His original prototype used cardboard, pressure sensors, accelerometers and an iPhone to make music, but the end design makes extensive use of 3D printing. Beatjazz uses repurposed saxophone fingerings and a sensor that captures breath exhalations.

The freedom of 3D printing is that when I want to evolve some aspect of the interface, I have only to redesign the part and print it. The ability to create something at home that is cooler than what you get from a big company is going to change the world. –Onyx Ashanti

Next up, Mad Mike of MTV’s Pimp My Ride fame will be, well, pimping out a Nissan Cube as part of 3D Systems’ Cube Odyssey to promote the company’s Cube 3D printer. The Cube Odyssey is a road trip that will hit 25 US cities beginning April 12. The trip will see the Cube stopping at monuments, schools and other interesting venues to showcase the Cube printer.

On the software front, a number of companies involved in additive manufacturing (AM) are looking to replace the standard STL files with a newer format. As some of you may know, STL files are great for surface mesh geometry, but don’t include information about materials, color, texture, labeling, build orientation and so on.

Enter additive manufacturing file (AMF), an XML-based open standard interchange format proposed as the replacement for STL, initially released by ASTM International Subcommittee F42.04, May 2, 2011, as ASTM F2915-11. As of December 2011, several companies have announced AMF support, including Materialise, netfabb and Sculpteo.

Last, we bring you news about RedEye on Demand, the rapid prototyping arm of Stratasys (Rapid Ready company profile here). The service has added cast urethane molding to its menu. Cast urethane molding is frequently used to quickly manufacture short-run production components. According to the company, cast urethane molding works well for prototypes as well as production runs of fewer than 100 parts.

With pressure to decrease the time and costs associated with bringing a product to market, there is increased demand for suppliers with full-service production capabilities — particularly in the medical, automotive and heavy machinery industries. –Richard Garrity, Stratasys vice president

Below you’ll find a video featuring Onyx Ashanti and his Beatjazz system.

Sources: Gizmag, PlasticNews, 3D Systems

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE