3D Printing Could Speed Up Your Internet

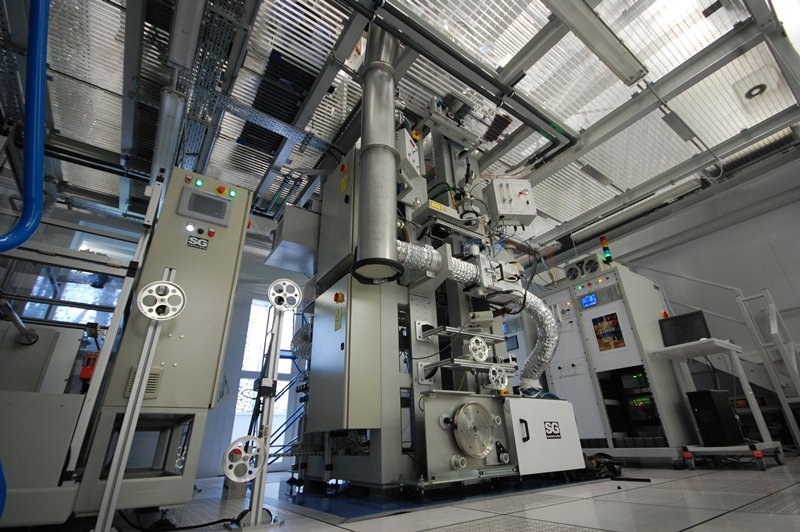

This silica drawing tower may become obsolete with the introduction of AM to fiber optic construction. Courtesy of the University of Southampton.

Latest News

July 6, 2015

There are plenty of things we still don’t have that were once touted as technologies of the future. Flying cars (totally impractical), virtual reality (almost), or interplanetary travel (unmanned, one-way only). It might just be that one technology most people never saw coming, the Internet, is better than crashing your flying car on the way to the moon.

The backbone of the Internet is miles and miles of fiber cable, running through the ground, along the sea bed, and so forth. The basic method for creating optical fiber is still basically the same as when someone first stretched out a piece of glass. Researchers at the University of Southampton are beginning research on developing new methods of optical fiber production using additive manufacturing (AM).

This silica drawing tower may become obsolete with the introduction of AM to fiber optic construction. Courtesy of the University of Southampton.

This silica drawing tower may become obsolete with the introduction of AM to fiber optic construction. Courtesy of the University of Southampton.Current methods of optical fiber production allow for a consistent structure along the length, but isn’t able to easily control shape and density. Those limitations restrict the design freedom of engineers when developing new optical fiber configurations meant to improve efficiency.

A new method of producing preforms is ready to begin testing at the University of Southampton. If successful, it will give engineers a new freedom of design to construct optical fiber exactly how they like where and when they like along the length of the cable.

“We will design, fabricate and employ novel Multiple Materials Additive Manufacturing (MMAM) equipment to enable us to make optical fiber preforms (both in conventional and microstructured fiber geometries) in silica and other host glass materials,” said Professor Jayanta Sahu. “Our proposed process can be utilised to produce complex preforms, which are otherwise too difficult, too time-consuming or currently impossible to be achieved by existing fabrication techniques.”

The new process will use ultra-pure glass powder to build optical fiber using AM, allowing researchers to specifically design each part of the fiber. In order for the project to succeed a number of hurdles need to be overcome, including, “… the high melting temperature of the glass (over 2000˚C in case of silica); the need for precise control of dopants, refractive index profiles and waveguide geometry; and the need for transitions between the layers to be smooth, otherwise the properties of the resultant fiber will be altered.”

Along with improving communications, success could offer potential applications for sensing technologies, metamaterial fiber cable, and high-powered lasers. Below you’ll find a video about current production methods for optical fiber.

Source: University of Southampton

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE