Students Design a Different Kind of 3D Printer

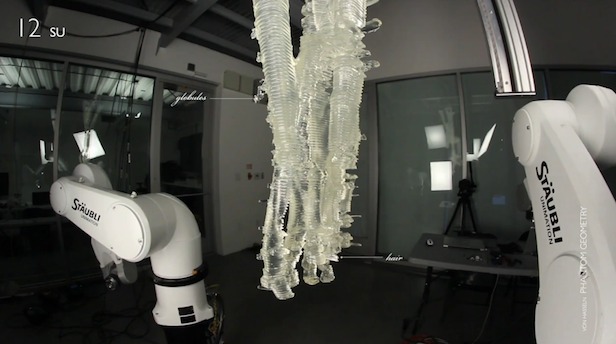

3D printed artistic architecture created using a customized system. Courtesy of Liz and Kyle von Hasseln.

Latest News

October 16, 2012

Another day, another new 3D printer. Yawn? I certainly don’t feel that way, and I doubt many of you good folks do either. It’s always interesting to see what the newest additive manufacturing (AM) system has to offer.

The printer I’m writing about today isn’t exactly what you might call standard issue. The build area is nebulous, the speed almost inconsequential, and it isn’t going up for sale any time soon. It is, however, innovative, and offers a new ideas about how AM can be used.

Husband and wife team, Liz and Kyle von Hasseln, used the resources made available to them at the Southern California Institute of Architecture (SCI-Arc) to create a unique 3D printer. The device includes a vat of photocurable resin, a UV “printer head” and six Stäubli robotic arms. The arms control the positioning of the printer head and that of the resin vat, allowing for a freedom of creation in every axis.

In the words of the von Hasselns:

This system is a full-scale, generative fabrication process that is innately non-linear, is interruptible and corruptible at any time, and does not rely on periodic flattening to 2D. Light is the medium for data in our system. There resident data can be drawn through physical space, at full scale, to generate a photographic artifact, or to instantiate material form through the selective polymerization of proximal photo-responsive resin.

Using a bit more terse vocabulary, that means that, rather than being built inside a machine with a viewing port, this 3D printer builds objects in the open. This allows the designer to get a good, close-up view of the object as it is being built. The combination of access and material choice offers an opportunity to alter the design at any point during the build, rather than waiting for it to be completed.

While it may not have been the von Hasselns’ intent, this process offers possibilities for rather more prosaic uses. One limitation of AM is the size of the build area. If that limitation is taken out of the picture, the technology becomes far more flexible by allowing larger objects to be created.

Of course, not everyone is going to have access to the highly sophisticated robotic arms used by the von Hasselns, but with some tinkering, I think this idea has some potential for industries that can afford similar setups. The husband and wife team won the first ever Gehry Prize from SCI-Arc for their creativity.

Below you’ll find a couple of different videos that recorded the von Hasselns’ Phantom Geometry project.

Sources: Fast Company, Web Pro News

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE