Mark X Adds Laser Inspection

October 18, 2016

Markforged has carved out a niche by offering desktop printers that embed continuous fiber into printed carbon and nylon to create extremely strong parts. Now the company has expanded its line of composite 3D printing solutions, and is offering in-line laser inspection to ensure the finished part meets the design tolerances of the original file.

Markforged has carved out a niche by offering desktop printers that embed continuous fiber into printed carbon and nylon to create extremely strong parts. Now the company has expanded its line of composite 3D printing solutions, and is offering in-line laser inspection to ensure the finished part meets the design tolerances of the original file.

The new Markforged Mark X is equipped with a high-precision build plate, encoders on the print head to improve accuracy, a high-stiffness Z-axis motor, and silent stepper motors. It can print with a 50-micron fine surface finish, and has a build volume of 330mm/250mm/200mm.

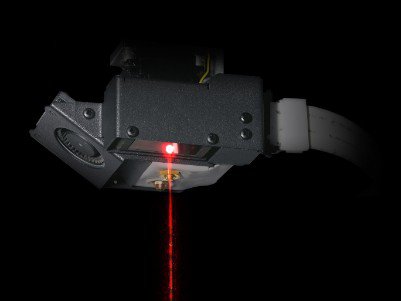

It also includes in-process laser inspection for dimensional accuracy, which the company says will give engineers and designers the ability to ensure printed parts match their design specifications. A laser sensor affixed to the print head will scan parts at any layer designated to measure whether critical tolerances are met using the company’s Google Chrome-based Eiger software.

Users can set up parts in Eiger to determine which layers will be scanned using the laser sensor. After the layer is scanned, details are accessible through Eiger. The user can check dimensions on the different aspects of the part using the scans. If the user is not satisfied with the dimensions of the print, they can cancel it.

“We have taken a different path from most of the 3D printing industry with innovation that will create a new bottom line benefit for many manufacturers,” said Greg Mark, CEO and founder. “We already had success with the breakthrough strength and light weight of continuous carbon fiber in our Mark Two printer; now we’ve added in-process inspection for exact dimensional accuracy, high-resolution beautiful surface finish, and scale to open entirely new segments of the industry to efficiencies of what printing can accomplish.”

“For over a year many of my customers have been interested in a Markforged 3D printer with a larger build volume,” says Daniel Held, CEO of Coffee GmbH, a value-added reseller of Markforged in Germany. “The combination of a large build size, in-process inspection, composite reinforcement, and the continued reliability and robustness that has become synonymous with Markforged 3D printers is a powerful solution.”

Earlier this year, Markforged received $20 million in Series B funding from Matrix Partners, Trinity Ventures and Northbridge Venture Partners. The Mark X will ship in the fourth quarter of this year at a retail price of $69,000.

Source: Markforged

Subscribe to our FREE magazine, FREE email newsletters or both!

About the Author

Brian Albright is the editorial director of Digital Engineering. Contact him at [email protected].

Follow DE