The Virtual Foundry Democratizes 3D Metal Printing

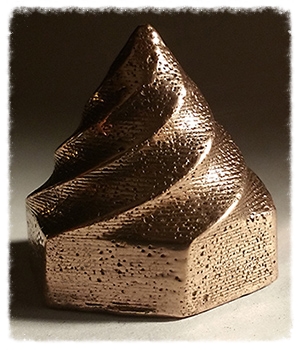

A part printed from Filamet and heat treated. Note the strata still present after firing. Courtesy of the Virtual Foundry.

July 6, 2016

It’s easy to make fun of buzzwords. They fly around and get used in marketing speak so often that they can end up not really meaning anything. “Democratization” is one of the buzzwords that have been circling around additive manufacturing (AM) for years. The term expresses the idea that AM gives manufacturing power to the people, allowing anyone with access to the tech the ability to produce (and maybe even sell) their own goods.

Although Marx would have cheered the prospect of people seizing the means of production, the democratization offered by AM has been fairly shallow. It’s reasonably easy to print out simple items, but complex manufacturing is still the province of big business. This is particularly true of metal printing processes. The Virtual Foundry offers hope that might not always be the case with the launch of its metal filament.

A part printed from Filamet and heat treated. Note the strata still present after firing. Courtesy of the Virtual Foundry.

A part printed from Filamet and heat treated. Note the strata still present after firing. Courtesy of the Virtual Foundry.The Virtual Foundry has named its new product Filamet, and its release is the result of a successful Kickstarter. Filamet is based on the same principle as precious metal clays (PMC), which suspend tiny bits of metal in a clay binder. In place of clay, Filamet suspends metal in a printable filament, though given the price of $85 per spool, Filamet contains more metal than plastic.

According to the company, Filamet will work with any 3D printer or pen capable of using PLA, which is where democratization comes into play. Giving people the chance to print metal on a $200 AM system is a step forward when some metal 3D printers can cost upwards of $1 million.

There is, of course, a caveat: While it is possible to print a metal model and just polish it up, building a useful metal part requires access to a kiln. Just like PMC, from which the idea of Filamet was born, an object can only really be finished following heat treatment in a kiln to both burn off the binder and sinter the metal particles together. A few makers might have easy access to a kiln, but it isn’t exactly a common household item.

Below you’ll find a video that demonstrates the prep necessary to heat an object printed with Filamet. It’s a bit messy, and won’t appeal to most casual users, but the promise of inexpensive metal parts might be worth the extra effort.

Source: The Virtual Foundry

Subscribe to our FREE magazine, FREE email newsletters or both!

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE