Northwestern Prints Terahertz Lenses

Latest News

May 17, 2016

X-ray technology is commonly used for inspection and security applications, but solutions based on terahertz radiation is quickly emerging as an alternative because of its ability to detect materials that X-rays miss.

A team of researchers at Northwestern University is using 3D printing to create lenses for these terahertz systems in a way that could reduce costs and speed adoption of the technology.

Falling between the microwave and infrared frequencies, terahertz frequencies can provide a a significant amount of information about ordinary materials and living tissue, which are semi-transparent to that type of radiation. And unlike X-rays, these systems can detect plastic, chemicals and biological materials — making them appealing for security applications.

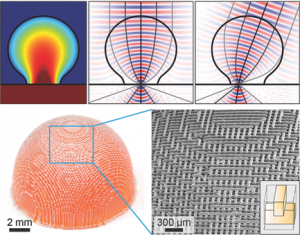

The Northwestern team created a terahertz lense using metamaterials and a projection microstereolithography 3D printing technique. Using this technique, the researchers were able to mold the metamaterial and create the miniscule features the lens requires.

This process could help lower costs and production time for the lenses. Currently, the terahertz lenses require additional components to ensure a clear image because of imperfections inherent in the grinding and molding processes.

“Typical lenses – even fancy ones – have many, many components to counter their intrinsic imperfections,” says Northwestern University’s associate professor of Mechanical Engineering, Cheng Sun. “Sometimes modern imaging systems stack several lenses to deliver optimal imaging performance, but this is very expensive and complex. For printing, we use a photo-polymer in liquid form. When we shine a light on the material, it converts it into a solid. The material forms to the shape of the light, allowing us to create a 3D structure.”

With the printed lens, a gradient index helps produce ultra-sharp images. The refractive index distribution can only be created via the printing process.

“This advance means we can unveil previously inaccessible information of some opaque materials in high resolution,” said Wei Cao, Sun’s collaborator at Oklahoma State University. “This opens up an entirely new technique for a massive range of potential uses from biomedical research to security.”

The team published their work in the journal Advanced Optical Materials in April.

Last year, researchers at Wuhan National Laboratory also printed terahertz lenses.

You can see the Northwestern printer in the video below.

Source: Northwestern University

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

Brian Albright is the editorial director of Digital Engineering. Contact him at [email protected].

Follow DE