Chemson Pacific Develops PVC for 3D Printing

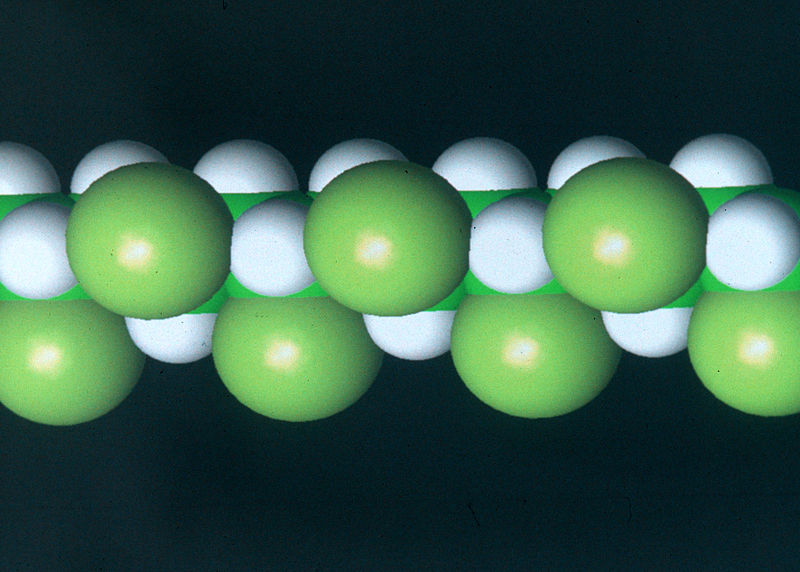

PVC has joined the AM materials family. Courtesy of CSIRO.

Latest News

May 18, 2016

As the technology behind additive manufacturing (AM) continues to grow and develop, materials development is starting to pick up the pace. In most cases the companies behind AM systems are not the same companies developing new materials. Generally, it’s more economical for 3D printer companies to produce printers that are flexible in material use, than to attempt to fill every material need.

Polymer materials represent what is probably the most commonly used AM material, at least for now. PLA and ABC are the usual suspects with proven characteristics to provide medium quality prints with almost any AM system. Australia’s branch of Chemson Pacific hopes to change the playing field with its new material called 3D Vinyl. While that might sound like an album hipsters would buy, the company says it represents the first PVC fit for 3D printing.

PVC has joined the AM materials family. Courtesy of CSIRO.

PVC has joined the AM materials family. Courtesy of CSIRO.“3D Vinyl is a definitive new 3D printing material that will bring a combination of physical properties not available with the current incumbent polymeric materials,” said Dennis Planner of Chemson Pacific. “3D printing is currently one of the fastest growing, value-adding industries internationally and will be an important source of mentally stimulating career paths and new business growth for the future, which I’m absolutely proud to be a part of. 3D Vinyl brings a new era for the PVC industry and advanced manufacturing, here in Australia and worldwide.”

According to the company, 3D Vinyl offers the following advantages:

- Low melt viscosity

- Excellent flow properties

- Heat stability

- Excellent layer adhesion

- Enhanced durability

PVC is one of the most commonly used plastics in the world, and this development further narrows the gap between conventional manufacturing and 3D printing. Below you’ll find a video about PVC.

Source: PR Wire

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE