Formnext International AM Conference Opens in Frankfurt

EOS new MeltPool monitoring system assists with build quality by monitoring objects during the build process. Courtesy of EOS.

Latest News

November 19, 2015

[gallery size=“medium” columns=“2” ids=”/article/rapid-ready/wp-content/uploads/2015/11/formnet_exhibitors.jpg|,/article/rapid-ready/wp-content/uploads/2015/11/formnext2.jpg|,/article/rapid-ready/wp-content/uploads/2015/11/formnext_opening_ceremony.jpg|,/article/rapid-ready/wp-content/uploads/2015/11/formnext.jpg|”]

If interest in a product or technology can be measured by the number of conferences dedicated to showcasing what it has to offer, then its certain interest in additive manufacturing (AM) continues to grow. For years, shows such as RAPID or Euromold were the best (nearly only) options to learn about new AM breakthroughs, and mingle with experts and industry insiders. As AM continues to gain steam, more conferences have become available, including the Inside 3D Printing shows, and now formnext.

Based in Frankfurt, Germany, formnext is underway now. It is being positioned as an alternative to Euromold for the 3D printing industry. While Euromold is the largest European conference, it isn’t solely dedicated to AM. With Formnext, however, the spotlight is firmly on the possibilities offered by 3D printing. With participants including AM heavyweights such as EOS, Stratasys, 3D Systems, Autodesk, and even HP, there is sure to be substance to go along with the shine.

“Our goal was to make a well-educated decision for the future of our company and for our industry,” said Adrian Keppler, CMO, EOS Germany. “After a thorough analysis of all possible alternatives, we feel that formnext has the biggest potential to become the long-term global AM lead show of the future, as such offering the best platform we can currently think of to support further extensive market development of the entire AM industry. We look forward to meeting all relevant AM players at this show in Frankfurt.”

Topics covered at the conference involve everything from dental prosthetics to engine construction. Audi is presenting a demonstration about the history of toolmaking, and how it has been impacted by 3D printing. Another interesting topic discussed at the conference examines when AM is and is not the best option for parts manufacturing.

3DS is showcasing showcase its “digital thread solutions” for software and 3D printing, demonstrating what it calls “the seamless design-to-manufacturing workflow” it enables. It will also demonstrate the ProX 100 Direct Metal Printer on the show floor.

No conference would be complete without new releases.

EOS is bringing several new solutions with it to formnext, including the EOS M 100 and the EOSTATE Meltpool monitoring system. The EOS M 100 is a direct metal laser sintering (DMLS) system that has been developed for the dental industry. The system is essentially a more compact version of EOS’ DMLS offerings, and is capable of producing dental crowns and bridges in both stainless steel and EOS’ own CobaltChrome dental material.

EOS’ new MeltPool monitoring system assists with build quality by monitoring objects during the build process. Courtesy of EOS.

EOS’ new MeltPool monitoring system assists with build quality by monitoring objects during the build process. Courtesy of EOS.The EOSTATE Meltpool monitoring system is perhaps of more general interest. Developed to work as an add-on to the EOS M 290 DMLS system, EOSTATE Meltpool works to ensure quality builds. The new system monitors each layer of a part as it is built using, “… two photodiodes located on- and off-axis, a camera adapter, a specialized signal amplifier and according spectral filters to separate process light from reflected laser light.” The system also provides part and material traceability, which should be welcome in an AM industry still working on standardization.

EnvisionTEC announced its new Micro Plus line of 3D printers at formnext and debuted its Vector 3SP industrial 3D printer. The Micro Plus line includes two variations, the Micro Plus Hi-Res and the Micro Plus Advantage. According to the company, the updated desktop solution features a new body style, a touchscreen and an integrated embedded PC with Wi-Fi capabilities. The Vector 3SP includes a newly introduced single-frame design and a 15-in. touchscreen monitor on a swing arm to control the built-in, stand-alone PC. All of EnvisionTEC’s current 3SP materials have been approved for use on the new machine, which has also been equipped with a blade system that the company expects will open up new material options in the future.

Ricoh, which launched an additive manufacturing services business last year, launched of its first 3D printer under the Ricoh brand at the conference. The RICOH AM S5500P is an industrial selective laser sintering (SLS) machine. It has a build area of 21.65x21.65x19.69 in. (550×550×500 mm). Ricoh has begun taking orders in Japan and says it will expand sales to Europe and other countries.

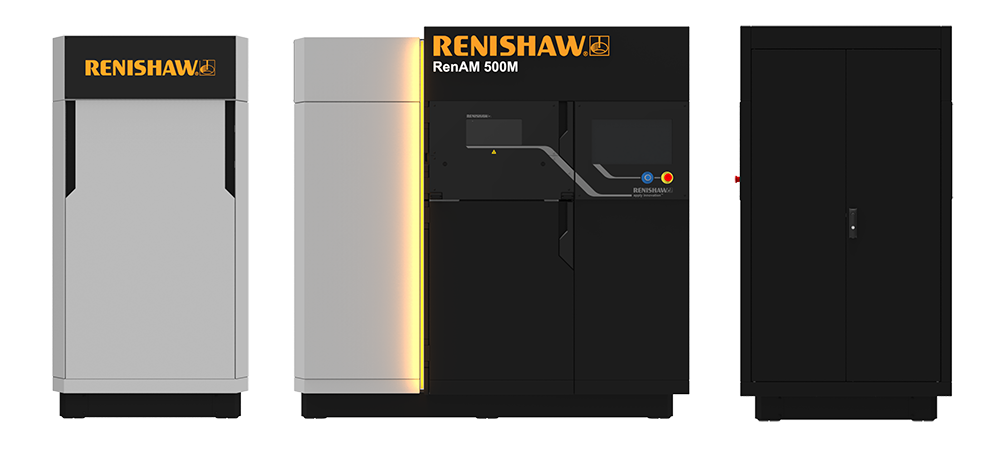

The RenAM 500M is a laser powder bed fusion additive manufacturing system from Renishaw.

The RenAM 500M is a laser powder bed fusion additive manufacturing system from Renishaw.Renishaw is showcasing its the RenAM 500M metal powder fusion 3D printer, its AM400 metal additive manufacturing system and QuantAM software for build file preparation. The company plans to open Renishaw Solutions Centres to provide a development environment for customers to expand their knowledge in using AM technology.

Stratasys introduced a new soluble support material, SUP706, for its PolyJet 3D printers. The company says it helps automate post-processing of 3D printed parts via a two-step, soak-and-rinse process.

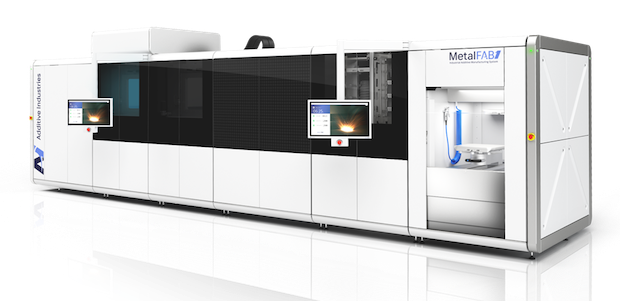

Additive Industries’ MetalFAB1 industrial 3D metal printing system.

Additive Industries’ MetalFAB1 industrial 3D metal printing system.Additive Industries presented its first industrial 3D metal printing system, the MetalFAB1. It is equipped with an automated build plate handling and in-line heat treatment, according to the company. Materialise is developing a customized version of its Build Processor software for Additive Industries to simplify the 3D printing process.

Sources: formnext

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE