MIT Prints in Glass

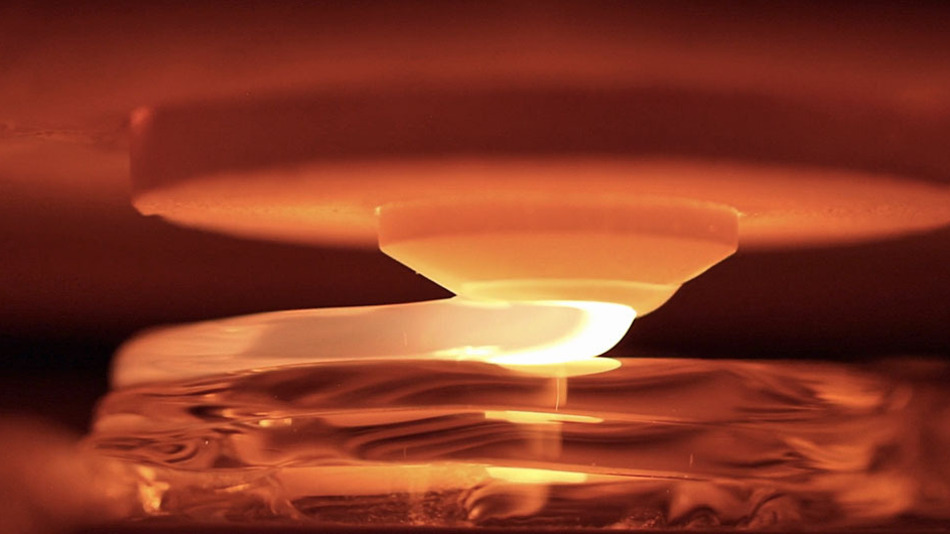

Molten glass is shaped into place with MIT’s G3DP process. Courtesy of the Mediated Matter Group.

Latest News

August 25, 2015

Materials drive gains in additive manufacturing (AM) technology as surely as new AM systems. Every time scientists add another material to AM’s portfolio, they increase the chances another business, or two, or 100, will adopt the technology. If AM has an evangelist, it might actually be the materials salesmen.

The Mediated Matter Group at MIT needs no such evangelist. With Neri Oxman leading the way, the Group has been developing new ways to use AM for years. Most of the Group’s work amounts to figuring out new materials to print with, and their most recent success is a method for 3D printing glass called G3DP.

Molten glass is shaped into place with MIT’s G3DP process. Courtesy of the Mediated Matter Group.

Molten glass is shaped into place with MIT’s G3DP process. Courtesy of the Mediated Matter Group.“G3DP is an additive manufacturing platform designed to print optically transparent glass,” according to MIT. “The platform is based on a dual heated chamber concept. The upper chamber acts as a Kiln Cartridge while the lower chamber serves to anneal the structures. The Kiln Cartridge operates at approximately 1900°F and can contain sufficient material to build a single architectural component. The molten material gets funneled through an alumina-zircon-silica nozzle.”

Along with the cool factor, the ability to print glass has a number of practical applications. While G3DP isn’t going to be competing with industrial levels of glass production, or that one really good glass blower you stopped to watch with your significant other on vacation, it does offer some advantages over those forms of production.

Accuracy and flexibility are always two of AM’s strengths, and that holds true for G3DP. In their paper covering the project, the Mediated Matter Group notes that glass developed for use in the aerospace industry offers the potential to improve performance by up to 40%. Aerospace is already a big fan of AM, generally for the lightweighting opportunities offered by the technology.

Communications technology is another area in which G3DP might make an impact. Fiber optics could be drastically improved by a process that created glass minus the imperfections. This is, in fact, already a project underway at the University of Southampton, where researchers are also using AM to improve how fiber optic cables are built.

3D printing glass also just looks cool. I mean, check out the video below. The flow of glass is kind of like a constant stream of honey.

Source: MIT

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DERelated Topics