3D Printed Legs are Next for Boston Dynamics’ Robots

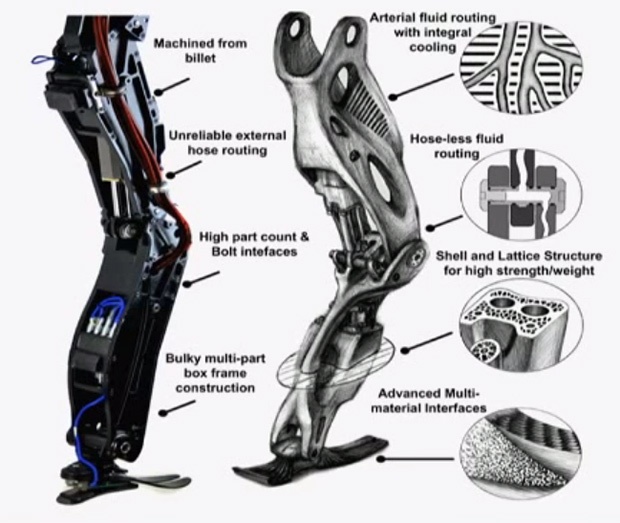

The left shows the current version of Atlas’ leg, the right is a concept image of a 3D printed leg. Courtesy of Boston Dynamics.

Latest News

August 18, 2015

Some very intelligent people, including luminaries such as Elon Musk and Bill Gates, have expressed concerns about exactly what might happen if we do manage to create artificial intelligence (AI). They seem to feel any AI is more likely to follow Skynet’s example than to follow Asimov’s Laws. None of that keeps people from working on new and increasingly sophisticated robots to act as servants for our forthcoming AI overlords.

Boston Dynamics, owned by Google and partially funded by DARPA, is one of the leaders in robotic research and manufacturing. The company is pursuing a number of different kinds of robots for a variety of different tasks, including one meant to walk more-or-less the same way as humans. During the FAB 11 Conference at MIT in August, Boston Dynamics founder Marc Raibert gave a short presentation that included some ideas about joining additive manufacturing (AM) and robotics.

The left shows the current version of Atlas’ leg, the right is a concept image of a 3D printed leg. Courtesy of Boston Dynamics.

The left shows the current version of Atlas’ leg, the right is a concept image of a 3D printed leg. Courtesy of Boston Dynamics.Amidst a video presentation that showed different types of robots navigating difficulties such as running through the woods or being kicked by Boston Dynamics employees, Raibert showed off a design for a 3D printed robotic leg. The design incorporated most of the design elements of a robotic leg into a single piece built during printing, rather than hundreds of smaller pieces made using traditional manufacturing.

“I can’t show you the robot yet, but we’re pursuing this pretty aggressively, and I think by the end of the year, you’ll see robots from us that use an approach of fabrication that’s more like that,” said Raibert.

Raibert expressed interest in lightweighting the legs by using a “honeycomb” pattern internally. This could be an important part of developing a robot than can travel outdoors under its own power. The Atlas robot seen running in the video was tethered to an external power source. A lighter robot would require less power to operate, and would have advantages crossing difficult terrain.

Below you’ll find Raibert’s presentation (forward to 26:07). I won’t say that seeing a robot running through the woods frightened me, but it might have made me uneasy. A little.

Source: YouTube

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE