Scientists Produce Cellulose-based 3D Printed Circuitry

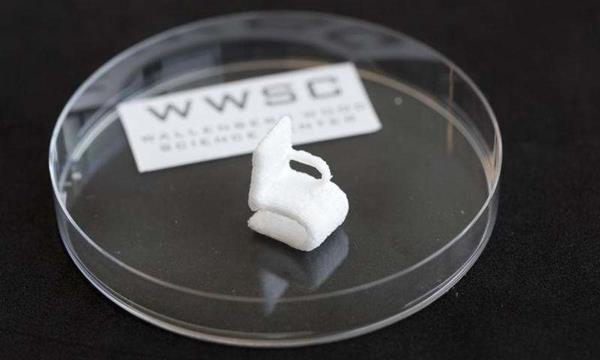

A tiny chair printed from a cellulose gel as proof of concept for Chalmer’s University. Courtesy of Chalmers.

Latest News

June 22, 2015

Wood is one of the most generally useful materials produced on the planet. People can build nearly anything from wood, and burn it to produce energy. Cellulose, the organic material generally found in tree trunks, has recently become popular for research into new additive manufacturing (AM) materials.

Swedish scientists from the Chalmers University of Technology have developed a method of printing cellulose objects. The research team was also able to mix its cellulose material with a different material in order to produce organically-based 3D printed circuitry.

A tiny chair printed from a cellulose gel as proof of concept for Chalmer’s University. Courtesy of Chalmers.

A tiny chair printed from a cellulose gel as proof of concept for Chalmer’s University. Courtesy of Chalmers.“Combining the use of cellulose to the fast technological development of 3D printing offers great environmental advantages,” said Paul Gatenholm, professor of biopolymer technology at Chalmers and the leader of the research group. “Cellulose is an unlimited renewable commodity that is completely biodegradable, and manufacturing using raw material from wood, in essence, means to bind carbon dioxide that would otherwise end up in the atmosphere.”

If you’ve ever roasted a marshmallow over a campfire, you’ve probably noticed that cellulose doesn’t melt when heated, it burns. This characteristic of cellulose makes it more difficult to work with than other materials, many of which can be readily melted down and formed into filament or resin.

The Chalmers research team overcame the problem by mixing cellulose nanofibrils in a hydrogel consisting of 95-99% water. The resulting gel could be fed into the team’s bioprinter and used to produced three-dimensional objects.

A wet glob of cellulose gel isn’t much good to anyone, so the team had to figure out the best way of quickly drying the printed objects to ensure they maintained a recognizable shape. The solution was to freeze dry the objects and to remove excess water while the objects were in a solid form.

Additional experimentation led the team to mix their cellulose gel with carbon nanotubes. This produced an ink capable of printing in three dimensions. Upon drying, the shapes formed by the mix are conductive forming 3D printed circuitry.

“Potential applications range from sensors integrated with packaging, to textiles that convert body heat to electricity, and wound dressings that can communicate with healthcare workers,” said Gatenholm. “Our research group now moves on with the next challenge, to use all wood biopolymers, besides cellulose.”

If you still aren’t sure where cellulose comes from, below you’ll find a quick review of your middle school biology class.

Source: Chalmers

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE