EDAG’s Light Cocoon Is A Metamorphosis for Car Design

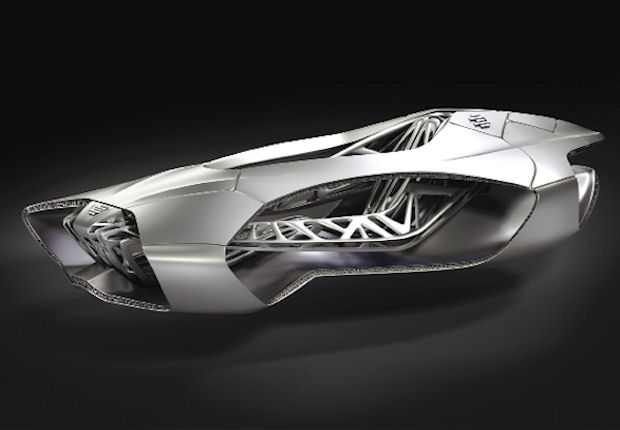

The EDAG Light Cocoon combines 3D printed vehicle structure with a weather proof textile outer skin panel. Image Courtesy of EDAG

Latest News

June 18, 2015

EDAG is getting ready to unveil its Light Cocoon concept car—a design that combines the power of 3D printing and biomimicry practices to take lightweighting to the next level.

As EDAG's 16th concept car, the Light Cocoon follows the GENESIS released last year to push the boundaries of automotive design and draw inspiration from nature. Both vehicles leverage 3D printing to produce the lighter weight, branch-like load bearing structures, but the Light Cocoon takes the approach further with the idea of separating the bone structure from the outer skin, according to Michael Pollner, head of marketing for EDAG.

The EDAG Light Cocoon combines 3D printed vehicle structure with a weather proof textile outer skin panel. Image Courtesy of EDAG

The EDAG Light Cocoon combines 3D printed vehicle structure with a weather proof textile outer skin panel. Image Courtesy of EDAGLooking at vehicle design in this way was a conscious break with existing paradigms, he explained. The current vehicle design and production model calls for cars to be developed with an outer metal structure that's integral to load-bearing requirements. Taking inspiration from natural elements like plant leaves, EDAG reimagined the relationship, bringing the functionality from the outer metal skin layer into a skeletal bone structure with the capacity to withstand forces, Pollner said.

“Traditionally, you couldn't separate the outer material layer from the structure because the metal skin was critical for withstanding all the physical forces,” he said. “Now we can bring this functionality to the skeletal structure, which is all about weight reduction.”

The Light Cocoon's design resulted in a spider-like, hollow structure that accommodates the assembly of aluminum profiles of different thicknesses. Stability requirements were met, Pollner said, and the team achieved a weight savings of approximately 25% thanks to the approach.

The EDAG Light Cocoon's branch-like 3D printed structure meets load-bearing requirements with less material. Image Courtesy of EDAG

The EDAG Light Cocoon's branch-like 3D printed structure meets load-bearing requirements with less material. Image Courtesy of EDAGAdvances in 3D printing were essential to breaking with traditional design conventions and taking the biomimicry approach. “When looking at production in the past, you couldn't do something like a skeleton structure—there was no way,” Pollner said. “Today, with 3D printing technology, everything is possible in every form.”

As far as lightweighting goes, the Light Cocoon's design isn't just about shedding a few pounds. “This is an entirely new dimension,” he said. “We're not just optimizing a little bit in the front or back of a car, we're exploring an entirely new idea, using 3D printing technology and combining it with the blueprint of nature.”

Accompanying the 3D printed bone structure of the Light Cocoon is a textile outer shell created with lightweight outdoor textile from a partnership with outdoor specialists Jack Wolfskin. The Texapore SOFTSHELL O2+ shell is a triple-layered polyester jersey fabric that is extremely lightweight, durable, and watertight. It provides weather protection for the vehicle, and the design team installed LED lighting technology behind the skin panel to showcase the skeleton-like, organic structure.

The EDAG development team also took steps to ensure the Light Cocoon looked more like a car as opposed to the GENESIS, which resembled a space ship or sphere.

The Genesis concept vehicle was designed to be manufactured as one singular part. Image courtesy of EDAG

The Genesis concept vehicle was designed to be manufactured as one singular part. Image courtesy of EDAGWhile Pollner says you're not likely to see the Light Cocoon or something like it on the road in the next few years, it's not completely futuristic. “With the Light Cocoon, we wanted to prove that it's not just about futuristic design and that we can really get this done,” said Pollner, adding that the design could become a production-class vehicle within the decade. “Sometimes when you're designing the cars of tomorrow, you have to think about the day after tomorrow.”

To hear more about the 3D printing process involved in the EDAG Light Cocoon, check out this video:

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

Beth Stackpole is a contributing editor to Digital Engineering. Send e-mail about this article to [email protected].

Follow DE