Carbon3D Debuts a New Kind of 3D Printing

Grown, not built, an object begins to emerge from the resin pool. Courtesy of Carbon3D

March 17, 2015

If you are at all familiar with additive manufacturing (AM), you probably realize that not all 3D printers operate in the same manner. Some systems jet materials, some fuse materials together, while the most common extrudes plastic. Though the processes may vary, each of them performs in pretty much the same way by building an object one layer at a time.

Joseph DeSimone, CEO and co-founder of Carbon3D would like to offer what he claims is an alternative method. Carbon3D unveiled its research and development to the public for the first time at TED 2015, demonstrating its CLIP system of 3D printing. According to DeSimone, the big difference between his system and other 3D printers is that CLIP “grows” objects, rather than building them in layers.

Grown, not built, an object begins to emerge from the resin pool. Image courtesy of Carbon3D

Grown, not built, an object begins to emerge from the resin pool. Image courtesy of Carbon3D“Current 3D printing technology has failed to deliver on its promise to revolutionize manufacturing,” said DeSimone. “Our CLIP technology offers the game-changing speed, consistent mechanical properties and choice of materials required for complex commercial quality parts.”

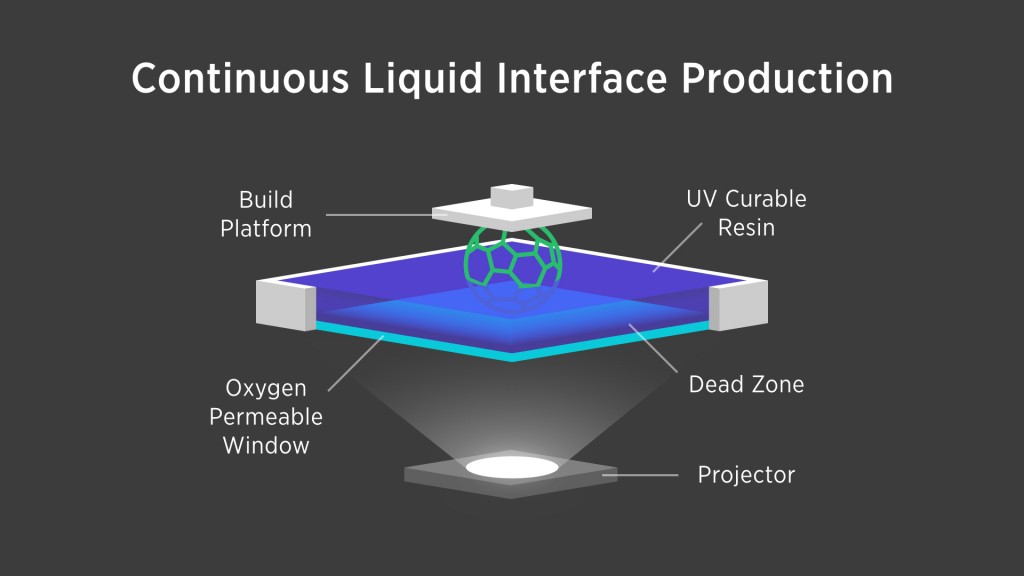

CLIP stands for continuous liquid interface production technology and operates through photo polymerization. If you think that sounds similar to existing AM processes (e.g. stereolithography), you’d be right, but only to a point. Rather than building an object one layer at a time by curing the topmost layer of a resin pool, CLIP projects light through the pool, encouraging the object to grow together simultaneously.

Here is the official explanation of the chemical processes that make CLIP work.

The heart of the CLIP process is a special window that is transparent to light and permeable to oxygen, much like a contact lens.By controlling the oxygen flux through the window, CLIP creates a “dead zone” — a thin layer of uncured resin between the window and the object.

This makes it possible to grow without stopping. As a continuous sequence of UV images are projected, the object is drawn from the resin bath. Sophisticated software manages the entire process by controlling the variables.

According to DeSimone, his process results in 3D printing that is 25 to 100 times faster than other processes, offers a broader range of polymer material choices and provides a higher quality of print. According to the company, objects built using the CLIP process have no strata lines, even when magnified 130x.

Carbon3D has already caught the attention of financial backers, so it might not be too long before the company has hardware to offer to interested parties. Additional information on the CLIP process can also be found in a paper published in Science named “Continuous liquid interface production of 3D objects.”

Below you’ll find a short video demonstration of the CLIP process.

Subscribe to our FREE magazine, FREE email newsletters or both!

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DERelated Topics