A Step Closer to the Future: 3D Printing with Graphene

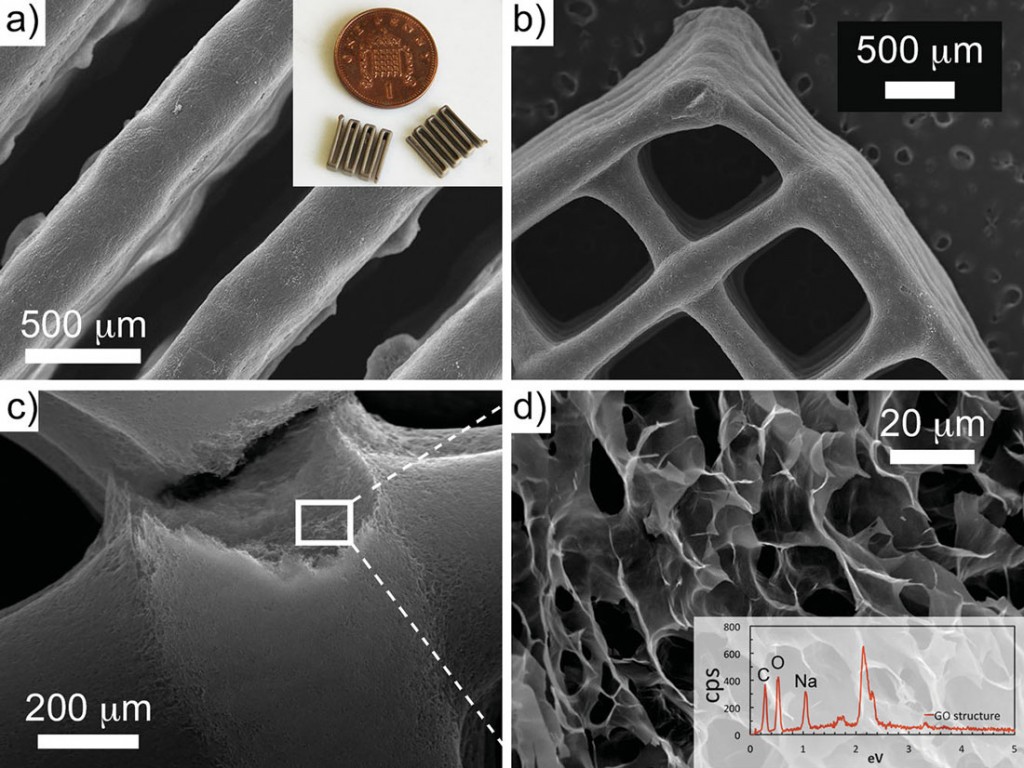

An up close look at the completed graphene structures. Courtesy of Advanced Materials.

Latest News

February 13, 2015

Graphene is the wonder material of the 21st century. Stronger and lighter than steel, highly conductive and so thin it is almost two-dimensional, scientists are finding all sorts of ways to use the material. It hasn’t quite been two years since Rapid Ready reported on exploratory research into how to run graphene through an additive manufacturing (AM) system, and now the waiting is over.

A team of researchers from Imperial College London, and the University of Warwick, have successfully 3D printed small structures with graphene. Other researchers around the world have had success with printing simple nano-structures with graphene, but this is the first time complex structures have been created.

An up close look at the completed graphene structures. Courtesy of Advanced Materials.

An up close look at the completed graphene structures. Courtesy of Advanced Materials.In most cases, scientists would make a 3D printing “ink” that combined the material in question with water that could be fed into a system. That process turned out to be more difficult with graphene because the material is highly hydrophobic. To produce a material that could be used for AM, the team used chemically modified graphene, known as graphene oxide (GO).

GO doesn’t have as much trouble mixing with water as untreated graphene, so was able to be added to the ink. Following a successful build, GO can then be thermally treated in a specific atmosphere to return to its graphene roots.

“Our formulations have the flow and physical properties we need for the filament deposition process required in 3D printing: They need to flow through very small nozzles and set immediately after passing through it, retaining the shape and holding the layers on top,” Dr. Esther García-Tuñon, a research associate at the Centre for Advanced Structural Ceramics at Imperial College London (ICL), told Nanowerk. “We use this two-dimensional material as building block to create macroscopic 3D structures and a technique called direct ink writing (DIW) also known as direct write assembly (DWA), or Robocasting.”

The results of the research can be found in the paper titled “Printing in Three Dimensions with Graphene” that was published in Advanced Materials. The research team is still working on practical applications for its discovery and warns that people shouldn’t get too excited about the 3D printing angle just yet.

Below you’ll find a video about the research.

Source: Nanowerk

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE