Princeton Builds Quantum Dot LED 3D Printer

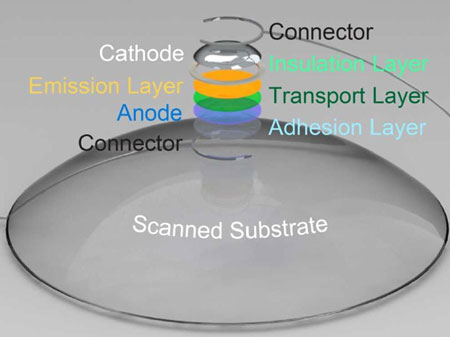

The quantum dots are built in layers, with a silver nanoparticle base which allows for conductivity. Courtesy of Princeton.

November 6, 2014

Additive manufacturing (AM) has come a long way from a process mainly used for prototyping. Now, almost anything can be built using AM, and if it can’t, that doesn’t mean someone won’t try. If you read enough AM news, it can start to seem that all the biggest advances in the medical and tech fields are coming thanks to some kind of involvement with a 3D printer.

A group of researchers at Princeton are the latest to apply AM to technical problems. The team was experimenting with ways of manufacturing quantum dot LEDs, and decided to build a new AM system specifically designed for that task. Six months of work and $20,000 later finds the team in possession of the first system that can build quantum dot LEDs composed of up to five different materials.

The quantum dots are built in layers, with a silver nanoparticle base which allows for conductivity. Courtesy of Princeton.

The quantum dots are built in layers, with a silver nanoparticle base which allows for conductivity. Courtesy of Princeton.The ability to mix materials to produce an LED works in similar fashion as Stratasys’ PolyJet systems, though at a much smaller level.

“The big push in 3D printing these days is to try to print two or more polymers at once,” Michael McAlpine, an assistant professor of mechanical and aerospace engineering at Princeton University, told Nanowerk. “In our latest research, we go way beyond that. We show that we can print interwoven structures of quantum dots, polymers, metal nanoparticles, etc, to create the first fully 3D printed LEDs, in which every component is 3D printed.”

Why should we care about quantum dot LEDs? Big technology firms are looking at quantum dot LEDs as the next evolution of display technology. Individual dots can be turned off and on to save power, and the image created by this type of LED is crisper than anything available today. Quantum dot LEDs are also less prone to wear and tear than other types of LEDs, leading to longer product lifecycles.

Along with building the 3D printer and testing its production capabilities, the Princeton team has used its 3D capabilities to print on different types of shapes and surfaces. From the paper titled “3D Printed Quantum Dot Light-Emitting Diodes:”

By further incorporating the 3D scanning of surface topologies, we demonstrate the ability to conformally print devices onto curvilinear surfaces, such as contact lenses. Finally, we show that novel architectures that are not easily accessed using standard microfabrication techniques can be constructed, by 3D printing a 2 × 2 × 2 cube of encapsulated LEDs, in which every component of the cube and electronics are 3D printed. Overall, these results suggest that 3D printing is more versatile than has been demonstrated to date and is capable of integrating many distinct classes of materials.

Below you’ll find a video about quantum dots.

Sources: ExtremeTech, Nanowerk, Nano Letters

Subscribe to our FREE magazine, FREE email newsletters or both!

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE