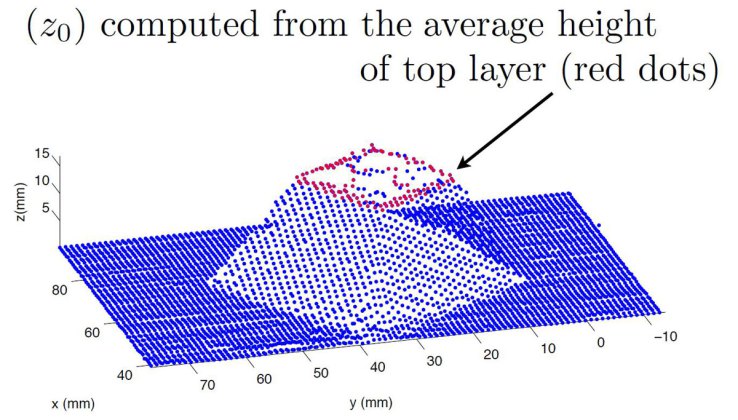

The scanning system develops a point cloud model during the printing process.Courtesy of Claudio V. Di Leo.

Latest News

August 1, 2014

Anyone who has worked with a 3D printer for any length of time knows the frustration of a bad print. At best you’ve just wasted some time and materials, at worst the prototype you were hoping to show to a prospective client has been ruined.

MIT students Claudio V. Di Leo, Louise E. van den Heuvel, and Sumant S. Raykar may have the solution to your 3D printing woes. The group has developed a system capable of scanning an object in-situ and comparing that scan to the original digital design. The system can also help to integrate two 3D printed objects together more smoothly.

The scanning system develops a point cloud model during the printing process.Courtesy of Claudio V. Di Leo.

The scanning system develops a point cloud model during the printing process.Courtesy of Claudio V. Di Leo.Just like most other 3D scanners, the system developed at MIT uses a laser to capture data, creating a point cloud model of the object currently being built. That model is checked against the original design. If something has gone wrong, the print can either be halted or the printer can be instructed to build missing parts to complete the build. Used intentionally, the system could allow for printing in multiple colors with a single print head, or just to add to an existing object.

The students designed their system using an expensive industrial laser, but claim a less expensive laser (in the $30 range, even) could work just as well. Testing was performed on a Solidoodle, so it seems logical to assume the system would operate basically the same if attached to other material extrusion printers.

While there’s no doubt the new invention would have consumer appeal, the MIT student team has decided not to commercialize the system. Instead they plan to go open source with the design, which should help iron out any bugs in the system fairly rapidly. This will be a great help to anyone with a material extrusion printer, but it seems less likely a similar system could be developed for processes that require a powder bed or resin tank.

Below you’ll find a video about the invention.

Source: TechCrunch

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE