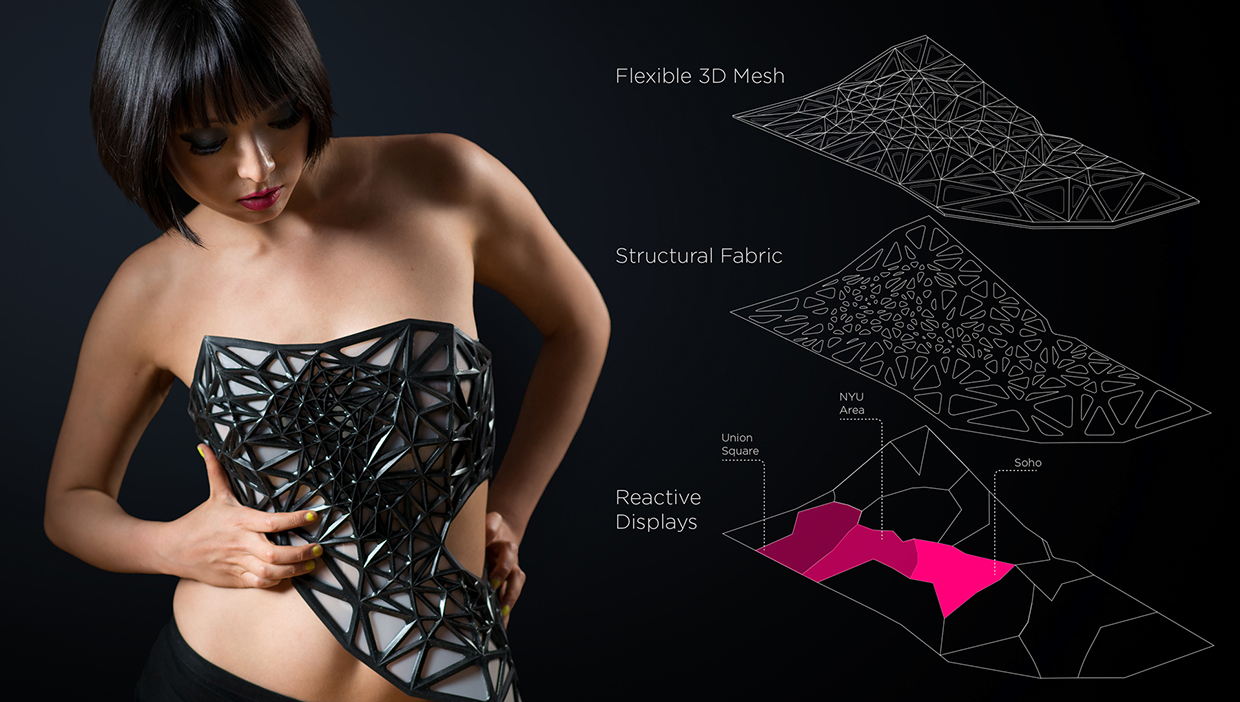

This piece of 3D printed wearable tech emphasizes the transparency of online privacy. Courtesy of x.pose.

Latest News

June 26, 2014

In the course of my diligent efforts to keep you good people up to date on the state of additive manufacturing (AM), I come across many interesting news items. I’ll gather them up every so often and present them in a Rapid Ready Roundup (like this one). You can find the last Roundup here.

We’ll start today’s Roundup with some news from 3D Systems. Earlier this month, 3DS signed a deal with Konica Minolta to act as a distributor for 3DS’ AM portfolio. The deal includes both direct sales and Konica Minolta’s US network of dealers and authorized resellers. The first AM systems to be offered as part of the deal will be the ProJet 3500 and the ProJet 660.

“Our goal is to arm our nationwide, exceptional sales organization with the cutting-edge products and services they need to grow their businesses and gain a competitive edge,” said Kevin Kern, senior VP, marketing, Konica Minolta USA. “By teaming up with 3DS, the recognized industry leader, and offering the most comprehensive suite of 3D printers materials and services, we’re able to do just that.”

Next up, Adobe is expanding Photoshop’s 3D printing options by adding Sculpteo as a supported service bureau for finished digital designs. Adobe began supporting 3D printing functionality in January of this year as part of Photoshop CC. The software initially only supported Shapeways as a built-in service bureau, but this move certainly signals Adobe’s willingness to branch out.

Photoshop has also added a feature that can estimate the total cost of materials needed to build a print, based on the final design specs. Each company will charge slightly different prices for finished objects, but adding a specific service bureau’s pricing information to Photoshop is as simple as downloading a file and dropping it into the proper folder.

This piece of 3D printed wearable tech emphasizes the transparency of online privacy. Courtesy of x.pose.

This piece of 3D printed wearable tech emphasizes the transparency of online privacy. Courtesy of x.pose.Moving on, New York University students Xuedi Chen and Pedro Oliveira have delivered an interesting piece of visual art in the form of a 3D printed top. While 3D printed clothing isn’t exactly new, this piece of wearable tech is intended to remind onlookers of how much information you reveal about yourself every time you post something online (not even including drunken Facebook posts).

The top is constructed of a 3D printed mesh integrated with a material that reacts to the wearer’s data transmissions. Each time the wearer offers up more material for the web to absorb, a panel turns transparent. In the end, the wearer is nearly naked. The x.pose project is Chen and Oliveira’s commentary on the state of online privacy, and is part of the duo’s Interactive Telecommunications thesis.

Last for the day, Google, EOS, and Shapeways are teaming up in an effort to increase interest in STEM studies among girls with the Made with Code program. At the simplest level, the program offers girls a chance to “code” a digitally designed bracelet through a few simple steps. The finished bracelet can then be translated to reality for free thanks to Shapeways.

Meatier parts of the Made with Code program offer to introduce girls to women that are active in computer science, make it easier to find local tech-based camps or educational events, and include links to basic programming sites. Below you’ll find the Made with Code intro video.

Sources: Made with Code, x.pose, Sculpteo, 3DS, Jezebel

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE