RAPID Happenings, Part 2

June 13, 2014

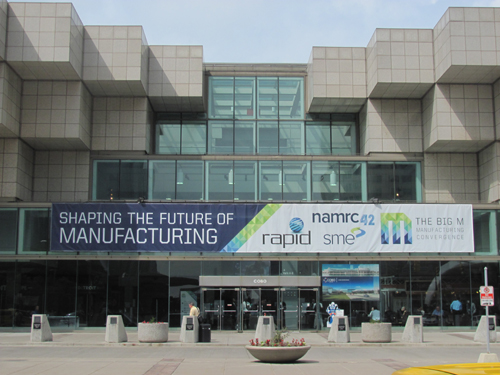

Another RAPID has come and gone, but while the show might be over, the same isn’t true for the additive manufacturing (AM) news it spawned. You can also have a look at our earlier coverage of the event.

Although it might seem obvious to some, probably the best reason to visit RAPID isn’t to see the new AM systems, or play with 3D printed parts, it’s to talk to the people behind those systems and parts. This year the main focus of many of the conversations I had or listened to were focused on two items of interest: materials and testing.

For most people attending RAPID, the “gee whiz” factor of 3D printing has begun to fade. That shiny, new feeling has been replaced by concerns about how the technology can improve and make bigger headway into the various manufacturing fields, particularly the trinity of aerospace, medical, and automotive.

Rather than talking to me about systems and processes, every service bureau and AM manufacturer seemed eager to tell me about which materials they offered. One exhibitor broke it down even further by suggesting the great divide in AM wasn’t process, but the difference in potential between plastic and metal 3D printing.

I also heard repeated concerns (mainly from attendees) about the costs associated with AM materials. People seemed more interested in systems that could use standard materials, rather than those materials specifically created for 3D printing.

Quality assurance (QA) was the other main topic of conversation that seemed to be floating around on the showroom floor and through the convention halls. This is another area in which AM has a long way to go in order to make up ground on traditional manufacturing methods. Not only does the industry need to work on finding ways to certify 3D printed parts, but it needs to discover methods of doing so in a timely and accurate fashion.

This larger than life 3D printed bust, created by Legacy Effects and Lightstorm Entertainment, was a popular object of attention on the showroom floor.

This larger than life 3D printed bust, created by Legacy Effects and Lightstorm Entertainment, was a popular object of attention on the showroom floor.The AM industry is receiving help from a number of entities in developing rigorous testing methods, including Oak Ridge National Laboratory, America Makes, ASTM, and a growing number of academic or privately owned institutes around the country. The few companies willing to discuss QA were those with procedures in place, and generally these were the same companies that produce metal parts or metal AM systems.

This year’s RAPID seemed like the largest yet. Certainly the showroom floor was more packed – both in terms of attendees and exhibitors – than I remember from past events. Next year is sure to attract even larger crowds, so start planning to attend early. Below you’ll find a presentation of the entries in this year’s contemporary art exhibit.

Subscribe to our FREE magazine, FREE email newsletters or both!

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE