Microsoft Adding Plug-And-Play 3D Printing to Windows OS

In upcoming Windows OS 8.1, the free 3D Builder app is expected to turn 3D printing into a plug-and-play function.

Latest News

May 7, 2014

If Microsoft could have its way, printing objects with 3D printers from Windows PCs would be as simple as printing from a common 2D inkjet printer. The company wants people to think of 3D printing not as a complicated process accessible only to the experts. It wants 3D printers to become plug-and-play devices.

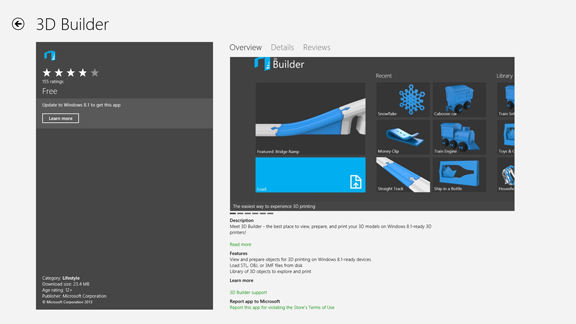

In upcoming Windows OS 8.1, the free 3D Builder app is expected to turn 3D printing into a plug-and-play function.

In upcoming Windows OS 8.1, the free 3D Builder app is expected to turn 3D printing into a plug-and-play function.Two weeks ago, at Congress On the Future of Engineering Software (COFES, Scottsdale, AZ, April 24-27), Kris Iverson, Microsoft’s principal development lead, and Simon Floyd, Microsoft’s director of innovation and PLM, hosted a tech briefing on additive manufacturing. Iverson views 3D printers as “powerful devices to help you realize what you’re thinking.” But there are some barriers to widespread adoption, even in the professional design and engineering community. Floyd said, “The material is expensive, the machine is costly, so companies sometimes stop the younger engineers from experimenting with additive manufacturing.”

The 3D printer Iverson and Floyd brought along to the tech brief — a $600 MakerBot machine targeting consumers — offers some clues to Microsoft’s strategy. “Even for the professionals, a professional 3D printer may not be affordable. That’s why we focus on a consumer printer,” said Iverson.

At $7,000 - $20,000, professional 3D printers are ideal for prototyping close-to-production designs, but may not be suitable for liberal use in the early phase where engineers may need to try out dozens of design variations in order to identify one winning idea. A low-cost consumer machine that occupies less space and doesn’t generate heat or noise, on the other hand, is a better choice, in Microsoft’s reasoning.

Floyd observed, “3D printing is not plug and play [at the moment]. Somewhere between plug and print, there’s a number of steps to repair the model.”

That’s where Microsoft sees an opportunity to play a role. Accordingly, the company struck a partnership with Netfab to launch a cloud-hosted model-repair service. Simply dubbed Model Repair Service, the Microsoft-Netfab portal lets you upload your model, automatically analyze and fix the geometry to make it print-ready, then return the repaired model.

In Windows 8.1, Microsoft’s free 3D Builder app is expected to further promote the idea of plug-and-play 3D printing. It offers direct links to downloadable 3D models, ready for print.

Though STL currently stands as the de facto standard for 3D printing, Microsoft is introducing its own file format, 3MF (3D manufacturing format), with color support. The company is currently in talks with CAD software developers to offer 3MF export functions from mainstream CAD programs.

Microsoft’s embrace of 3D printing, as evident in its push to integrate it into the operating system itself, marks a significant milestone. Its emphasis on affordable, consumer-level machines may prompt many 3D printer makers to rethink pricing, introduce more affordable printers, or realign some of their offerings to be consistent with Microsoft’s approach.

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

Kenneth Wong is Digital Engineering’s resident blogger and senior editor. Email him at [email protected] or share your thoughts on this article at digitaleng.news/facebook.

Follow DERelated Topics