SOLS Systems Excites Investors with 3D Printed Orthotics

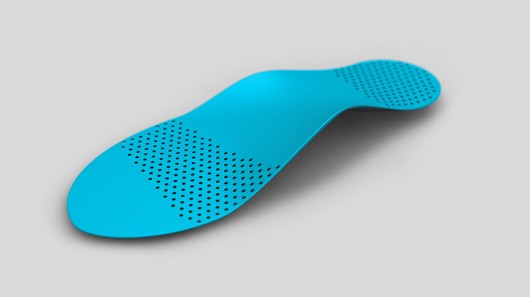

SOLS uses digital scanning and 3D printing to build custom orthotics. Courtesy of SOLS.

Latest News

April 30, 2014

Even with planes, trains and cars, much of our day-to-day transport needs are still filled by the old shoe leather express. The more people walk, the more likely they are to develop problems with their feet and legs. Many of these problems can be fixed or eased by using medical insoles, also called orthotics.

SOLS Systems is a new company that has turned to additive manufacturing to produce its own line of orthotics. The company raised $1.75 million in seed funding last December, and will be adding an additional $6.4 million in Series A funding led by Lux Capital. So what’s all the fuss about?

With an aging population, medical devices that are relatively easy to manufacture and sell will continue to gain in popularity. In the case of SOLS, the company has found a vacuum in which to develop its product. Although medical insoles aren’t a new idea, the orthotics have traditionally been made using old techniques for measurement, such as creating outlines of patient’s feet with paper or casts.

SOLS has brought digital technology to the orthotics field. Working with around 50 podiatrists to test out the system, the company provides a means for digitally scanning a patient’s feet to produce super accurate, 3D designs for medical insoles. The designs are then sent to a 3D printer, which builds a custom insole from flexible nylon. The insoles can then be dyed to customer preference, and are treated with an antimicrobial coating to reduce odor.

“Foot mapping provides a pressure map of the foot,” Kegan Schouwenburg, SOLS CEO told Gizmag. “At Sols, we are replacing the need for casts and fiberglass models of the foot with a 3D model collected via a series of complex algorithms. Our 3D scans are made up of hundreds of thousands of unique individual points across the foot and ankle.”

The latest round of investments should give SOLS enough time to get production rolling, while still retaining valuable staff members. Additionally the company would like to move into other areas of medical technology, along with offering the basic SOLS insoles to the general public.

SOLS’ orthotics are only the latest improvement in medical technology to come via 3D printing. It’s fair to say that medical AM has become a field all its own, and a rapidly expanding field at that. With prosthetics, implants and eventually 3D printed organs, AM seems to be a technology that doctors didn’t know they’d been waiting for all along.

Below you’ll find an overview of SOLS.

Sources: Gizmag, New York Times

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DERelated Topics