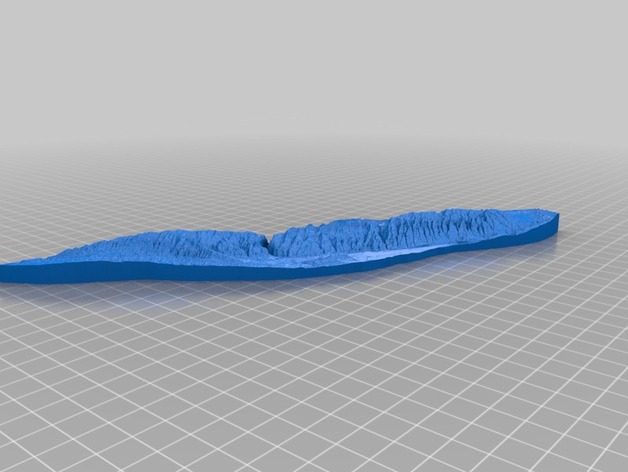

Printable 3D image of Sheep Mountain in Wyoming produced by the ISU GeoFabLab. Courtesy of Thingiverse.

Latest News

November 7, 2013

Additive manufacturing (AM) may end up being one of the most versatile tools to ever hit the shelves. The technology can produce food and assist operations, along with providing rapid prototyping and end-use capabilities for manufacturing. Researchers in any number of scholarly disciplines have found ways to use AM to improve their studies, and now geologists have joined their numbers.

The ability to visualize information in three dimensions is a necessity when studying many different aspects of geology, including topography, flow research, and strata. Geologists have been building their own scale models of key geological structures for years, eventually turning to three dimensional designs on computers when they became widely available. The GeoFabLab at Iowa State University (ISU) has begun experimenting with AM to build extremely accurate geology models that students and researchers can be see and touch.

From the GeoFabLab website:

The mission of the Geological Fabrication Laboratory is to develop and deploy novel techniques for describing and interpreting geology. This is accomplished by not only through a deep understanding of industry and academic techniques, but also by interactions with other fields of research like materials science and biotechnology where people are interested in porous materials, microscopy, surface chemistry, etc.

The GeoFabLab was founded by ISU geologist Franek Hasiuk, with funds provided by the university to purchase a MakerBot Replicator 2X and Digitizer 3D scanner. As a former petroleum geologist, Hasiuk wondered if he couldn’t take the 3D data provided by CT scans of porous rocks to print out models. His theory was that, if he was able to produce a model with enough detail, he could print models of rocks with and without fractures, to demonstrate the types of rocks in which oil and gas are regularly found.

Unfortunately, the Replicator 2X isn’t quite up to the task, but other departments at the university have access to more accurate AM systems, which will eventually allow Hasiuk to repeat his experiment with stereolithography. In the meantime, he has continued to use the Replicator 2X to build other types of models to help explain how geological features developed.

Hasiuk says giving students a chance to touch the models, and see them up-close has helped enormously, specifically his topographical models. It isn’t always easy to visualize the layers of geology, and the models make the process simpler. The models are also incredibly useful for blind students, giving them a chance to feel the shapes of the continents, and even the Earth itself.

Below you’ll find a video about printing a different kind of topographical map.

Sources: LiveScience,

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE