3D Printing Takes Its Vitamins

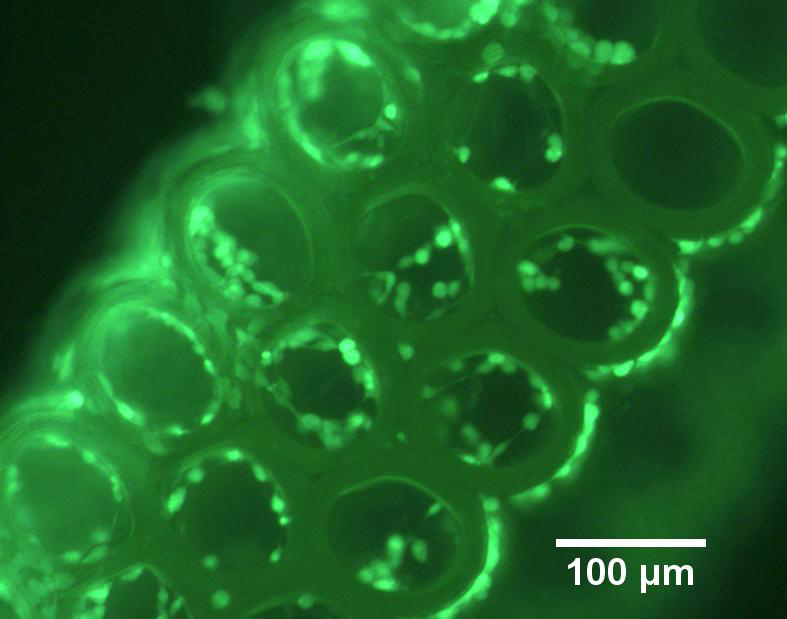

Riboflavin scaffolding built using additive manufacturing may be the key to biocompatible implants. Courtesy of NC State.

Latest News

November 5, 2013

Among all the industries additive manufacturing (AM) has made an impact in, the medical field may be the most important. Whether an AM device is saving a baby’s life or developing synthetic human tissue, the technology has the potential to improve lives in a very direct manner. Scientists have been hard at work developing 3D printed scaffolds to assist in growing tissue, to support grafts, or in the fabrication of implantable drug delivery systems.

The key to these procedures is the use of two-photon polymerization, which is capable of building nano scale structures. A potential issue with building these structures from polymers is the tendency for the materials to be toxic. Researchers at North Carolina State University (NC State) may have discovered a way to overcome this hazard by building the nano structures using riboflavin (AKA vitamin B2).

By mixing riboflavin with a precursor material, researchers have made the naturally occurring compound photosensitive, allowing it to be shaped by the two-photon process. Found in everything from asparagus to cottage cheese, riboflavin is nontoxic and biocompatible, making it an ideal candidate for use in patients.

“This opens the door to a much wider range of biocompatible implant materials, which can be used to develop customized implant designs using 3D printing technology,” said Dr. Roger Narayan, senior author of a paper describing the work and a professor in the joint biomedical engineering department at NC State and UNC-Chapel Hill.

Tests have thus far proved promising. Compared to standard polymers, riboflavin-based scaffolds were more compatible with living cells, allowing more cells to survive the implant process. While NC State researchers have admitted that the riboflavin mix used to build the scaffolds isn’t as easy to work with as polymer materials, they are confident that this shortcoming can be overcome.

More work, along with standard approval procedures, needs to be completed before the implants are ready to be used in medical implants, but this breakthrough could become extremely important for the future of medical 3D printing. The research was published online in Regenerative Medicine, under the title “Two-photon polymerization of polyethylene glycol diacrylate scaffolds with riboflavin and triethanolamine used as a water-soluble photoinitiator.”

Below you’ll find a short video about the riboflavin implants.

Sources: LiveScience, NC State

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE