Additive Manufacturing Aids in Construction of Low Cost Atomic Force Microscope

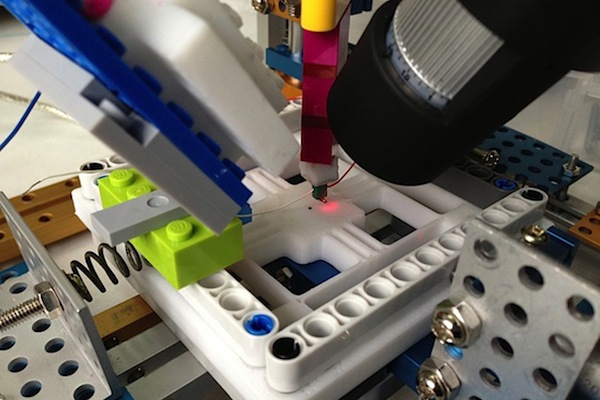

A closeup view of the atomic force microscope built from LEGO, 3D printed parts and commercially available electronic parts. Courtesy of UCL.

Latest News

October 7, 2013

Not only is additive manufacturing (AM) a useful tool for prototyping and production, it can also be used to seriously reduce costs. By now most people interested in the technology realize that an AM-built prototype can often be constructed more quickly and less expensively than prototypes built using traditional manufacturing methods. The same is true for end-use products.

Low-cost prosthetics are just one example of how AM can be employed to build functional products at a fraction of the usual price. Now, students from Tsinghua University, Peking University and University College London teamed up with the LEGO Foundation to develop another low-cost alternative product. Using LEGO, 3D printed parts, an Arduino board, and commonly available electronics, the students were able to build a functioning atomic force microscope (AFM).

An AFM is almost like a 3D scanner for nanoscale structures. It functions by noting the distance between the tip of the AFM probe arm and whatever object it is measuring. Repeated passes generate a 3D map of the object, giving scientists a chance to see nanoscale objects.

The LEGO AFM has 3D printed component holders and a scanning stage to go along with piezoelectric actuators controlled by Arduino processors and LEGO housings. Where most AFMs cost around $100,000 to purchase, the AFM developed by the students can be assembled for around $500.

The project hopes to make these microscopes available to children around the world, giving them a chance to see three-dimensional models of biological samples. Both the LEGO Foundation and the project team hope to inspire younger students to take a greater interest in science by giving them access to images beyond the standard 2D pictures found in textbooks.

Projects like this one lead me to believe that most schools would profit by having a 3D printer on site. Not only could they kids use the AM system to help build an AFM, but the information gathered could also be fed back into the printer to build 3D models of what had been scanned. That’s the sort of interactive education that grabs a child’s interest and keeps it.

Below you’ll find a short video about how AFMs work.

Sources: Wired, University College London

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE