3D Printed Reefs Provide Marine Habitats

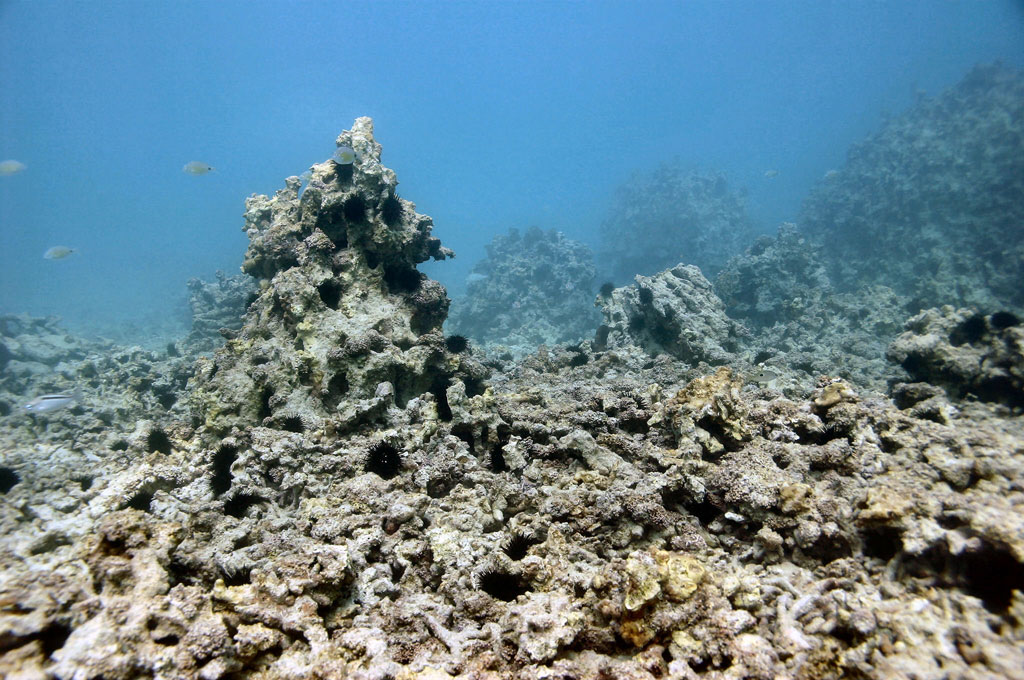

Artificial reefs like this one can help repopulate the seas near Bahrain. Courtesy of Reef Arabia.

Latest News

October 28, 2013

Whether you believe global warming is part of a natural cycle or is the result of human activity, it seems pretty certain at this point that the world is indeed getting warmer. The effects of this warming trend have seen glaciers melt, caused aberrant weather patterns, and raised sea levels. Other effects aren’t quite as obvious.

In addition to global warming, pollution, overfishing, and increased levels of coastal development have had a serious impact on coral reefs. According to the Australian Institute of Marine Sciences (AIMS) around 50% of the Great Barrier Reef has vanished over the last 30 years and the Persian Gulf has suffered similar losses. A project is underway outside Bahrain to replace missing coral reefs with 3D printed reefs.

Reef Arabia began working on the problem of Bahrain’s missing reefs in 2012. The company began by using concrete structures to replace the reefs. Some of these structures were built to mimic local buildings, while others were formed by stacking rows of so-called Reef Balls in place. The concrete mix used is non-toxic and should last for up to 100 years. Still, something was missing.

While providing a reasonable substitute for actual coral reefs, the concrete structures weren’t quite right. Seeking an alternative to concrete, Reef Arabia turned to the D-Shape 3D printing process. After building faux reef topology with the assistance of a computer program, two 1,100 lb. non-toxic reefs were constructed from a patented sandstone material, and then submerged.

“Sandstone, unlike concrete, is closer to a natural earth rock and has a neutral pH surface which makes it more attractive to coral larvae looking for a home,” David Lennon of Reef Arabia told Forbes. “With 3D printing we can get closer to natural design because of its ability to produce very organic shapes and almost lay down material similar to how nature does it.”

If you are unfamiliar with D-shape, it has an interesting history. Originally developed by Enrico Dini to build houses, the large-scale additive manufacturing process has since been put to other uses. Along with the reef project outside Bahrain, it won a contract to reinforce pilings along the New York City waterfront, and the ESA is investigating its use in building facilities on the moon.

Below you’ll find a video about Reef Arabia’s work on artificial reefs.

Source: Forbes

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE