Vader May Be the RepRap of Metal Additive Manufacturing

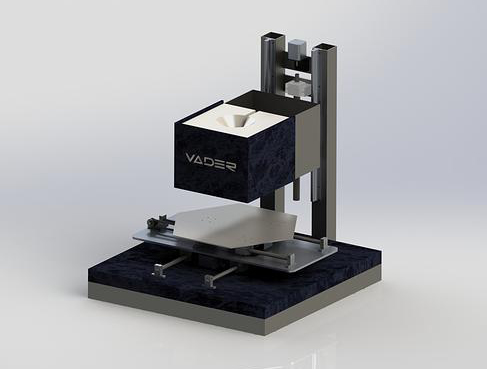

The prototype for the Vader metal 3D printer. Courtesy of Vader Systems.

September 26, 2013

The vast majority of home additive manufacturing (AM) systems build objects using the material extrusion process. The Cube, MakerBot models, and RepRap systems are among the most common, with lithography-based 3D printers such as Formlabs FORM 1 and the Peachy Printer, being among the exceptions.

For the most part, material extrusion printers are capable of producing about anything a hobbyist really needs to print, but these 3D printers do come up short when asked to provide replacements for anything made from metal. That may be changing. Father-and-son team, Scott and Zachary Vader, have developed a metal-based AM system that could appear in Maker spaces and, for wealthy users, potentially in hobbyist garages.

Called Vader, the 3D printer (still in development) is described by its creators as an inkjet printer for metal. To date, the AM system is only capable of working with aluminum, and does so by using magnetism to jet molten metal in patterns, slowly building up an object. Obviously aluminum isn’t inherently magnetic, so for metals that lack that quality, an electric charge is applied to the metal to encourage it along.

The Vader Mark I prototype has a build envelope of 250 x 250 x 250 mm (9.8 x 9.8 x 9.8 in.), which is large enough to be useful for hobbyist or small business purposes. It has a resolution of 50µ and a build speed of 20 mL/h. Beyond aluminum, the Vaders say they are looking at copper, silver and gold as the next materials to be added to the 3D printer’s material capabilities.

Moving the Vader from prototype to production may be something of a tedious process. The first units to be built will be custom jobs, and will run between $20,000 and $100,000. The creators hope to eventually get the cost under $10,000, which is still expensive for individual users, but there is another possibility for spreading the Vader.

Like the trusty RepRap, the Vader may be capable of reproducing itself. The system has the potential to build many of the components necessary for constructing another Vader from standard materials. Add the print head (which will still have to be purchased), and suddenly you have a new Vader for what is likely to be a fraction of the cost of buying a new system outright.

Here’s a link to a video about the Vader on Tom’s Guide, and below is something I couldn’t resist.

Sources: Vader Systems, Tom’s Guide

Subscribe to our FREE magazine, FREE email newsletters or both!

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE