Desktop 3D Printing Goes Big with gMAX

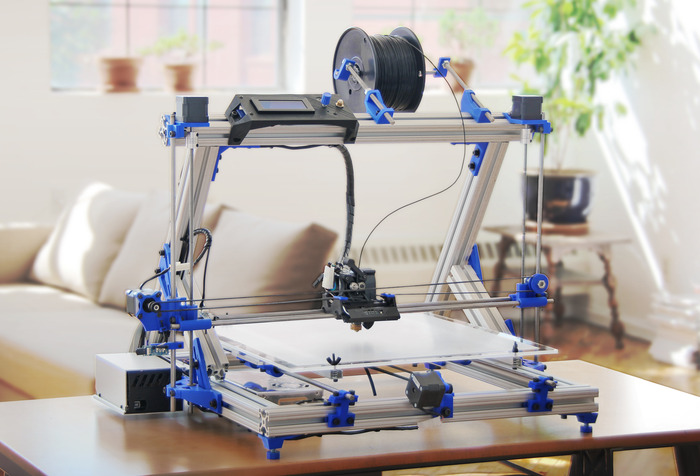

The gMAX 3D printer offers a large build envelope for a low price. Courtesy of gMAX Printers.

Latest News

September 3, 2013

I’m a pretty big additive manufacturing (AM) cheerleader. How can you not be a fan of technology that can produce everything from new ears to airplane wings? I also tend to believe that most of the limitations with current generation 3D printers can and will be solved by future advances in the field.

While the size of prints offered by desktop AM systems might not be considered a huge limitation, it does have an impact on consumers that require a certain build envelope for their work or home projects. It’s certainly possible to print out multiple parts of a larger object using a system with a small build envelope, but a larger build area allows for prints that are really meant to be one, solid piece.

The gMAX 3D printer breaks through the 8 x 8 in. paradigm to offer an AM system with a 16 x 16 x 9 in. (40.64 x 40.64 x 22.86 cm) build envelope. Designed by Maker enthusiast Gordon LaPlant, using 3D printed parts, the gMAX is modeled after the open source Prusa Mendel Rep Rap model.

As much as I loved the RepRap, I found myself being limited by the bed size. While I love the idea of sourcing parts from the community, there were larger objects I wanted to print but simply wasn’t able to. I then started playing around with designs for a larger 3D printer and eventually the idea started to grow legs and become something tangible. I sourced the latest electronics and a strong aluminum framework and used my RepRap to print the parts I needed to build what would become the gMax 3D printer. — Gordon LaPlant

Along with the 3D printed parts that helped to extend the build envelop, the system uses precision milled aluminum supports and an extruder module that can be replaced to perform other light production jobs, such as drill heads for drilling patterns, laser etching, CNC milling, or a roller blade for paper cutting. For professionals, strata lines may be an issue with the 3D printer’s 75µ layer height, but for users who are willing to put up with the lines, or capable or reducing them, the size of prints offered by the system may be worthwhile.

Another potential failing of the gMAX is that it comes as a kit. According to LaPlant, shipping the 3D printer as a kit reduces costs, and he claims the systems is easy to put together. I can’t vouch for the ease of construction, but at $1,300 for early backers, the gMAX is a low-cost option for such a large build envelope.

Below you’ll find the Kickstarter video for the gMAX.

Sources: Kickstarter, gMAX Printer

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE