Italian Startup Enters All-In-One Fabrication Fray

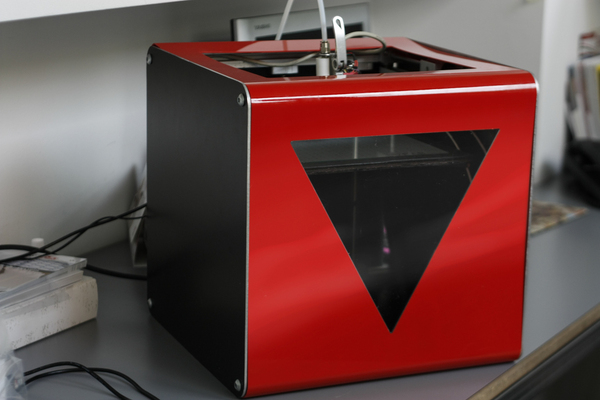

FABtotum’s Personal Fabricator is a desktop all-in-one manufacturing system. Courtesy of FABtotum.

Latest News

August 28, 2013

I remember a time not all that long ago when the Maker community was pleased as punch just to work with additive manufacturing (AM). They produced Yoda busts, chess sets and kitchen gadgets in ABS or PLA and rushed to show the results to the internet. Now, a new type of manufacturing system has entered workshops. These all-in-one devices still offer AM, but add in subtractive methods as well.

First we saw the Mini Proto Lab at RAPID 2013. More recently was Mebotics Microfactory. Today adds another competitor to the rapidly growing lineup of multifunctional manufacturing devices with Italian FABtotum‘s Personal Fabricator.

Fabtotum stands as “factotum”, a Latin word composed of facere (to do) and totum (everything). In the common language a Factotum is someone you would ask for help in any field, usually basic tasks, including humble jobs. Fabtotum however is not a renaissance servant. It’s a low-cost, hi-tech, computer-controlled, 3-axis machine capable of delivering a set of tools for hobbyist makers, architects, designers or developers. - FABtotum Blog

FABtotum’s all-in-one system offers material extrusion 3D printing, milling, four-axis machining, and 3D scanning. The AM side of the system prints to a 210 x 240 x 240 mm build envelope (8.2 x 9.4 x 9.4 in.), and has an extruder head designed to be interchangeable with third-party heads.

For milling and machining, FABtotum claims the system will work with a number of common materials including wood, light aluminum and brass alloys. The Personal Fabricator offers PCB milling, engraving, and CNC pre-drilling. It is worth noting that this isn’t a heavy duty industrial fabrication system. While the Personal Fabricator is capable of milling and machining, it can only perform those functions on relatively light materials, such as balsa, foam and light woods.

The scanner has the benefit of being part of a system designed to turn, so hands-free 360° scans are possible. No real word on the quality of the scans, just yet. The entire system looks to be designed to appeal to small businesses or Maker spaces where combined resources can be put into buying new machinery for the entire group.

Launched a little over a week ago on Indiegogo, the Personal Fabricator has already raised $45,000 of a $50,000 goal. You can get a Personal Fabricator for $849 while the crowdfunding effort is still underway, which is a bit less expensive than the other offerings in the field.

Below you’ll find a video about FABtotum’s Personal Fabricator.

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE