Additive Manufacturing Leveraged for Composite Construction

Latest News

August 16, 2013

Everything can be broken down into its component parts. You are composed of cells, your car is made of a pile of metal and plastic, and even your pen is built from multiple components. When it comes to truly large-scale construction of buildings or machinery, the number of parts involved runs into the thousands.

Scientists at MIT want to simplify construction by, paradoxically, increasing the number of parts required to build something. Kenneth Cheung and Neil Gershenfeld have developed a system of identical interlocking composite parts that can be assembled to build just about anything.

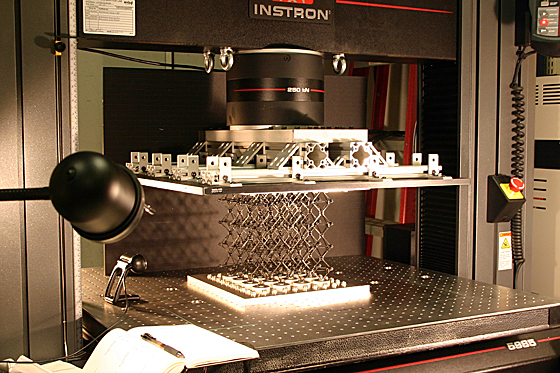

The duo’s idea combines the fields of fiber composites, cellular materials, and additive manufacturing (AM). Each fiber composite part is built on a 3D printer to the exact same specifications. From there, the parts can be snapped together and assembled like LEGO to build everything from spacecraft to levees.

As the parts go together, they form a composite lattice that is stronger than conventional constructions. Even better, because the lattice isn’t a solid mass, parts built using the process are lighter than standard components. According to the research team, the parts are stronger as well, as result of the lattice spreading out damage. In the case of damage, sections of the lattice can be replaced or repaired, rather than scrapping the damaged part.

Cheung and Gershenfeld have begun to design a robot to put together their composite pieces, further simplifying the construction process. The MIT team has published a paper in Science about their construction plan titled “Reversibly Assembled Cellular Composite Materials.”

Below you’ll find a video about the MIT Media Lab.

Source: MIT

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE