NASA Invests $100,000 in Bioprinting

The new bioprinting process makes materials and objects by gathering materials from the air. Courtesy of NASA

Latest News

July 31, 2013

Some of the most impressive parts built through additive manufacturing (AM) won’t be designed for planes, trains or automobiles. Bioprinting could build new organs, skin and various other body parts, revolutionizing how medicine is practiced. As more and more organic materials find their way into other fields (such as electronics), bioprinting could end up being the most important field of AM.

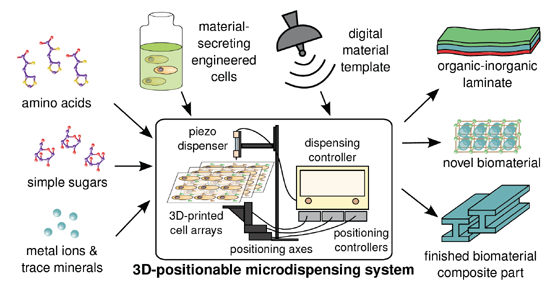

NASA, already an early adopter of AM, is now ready to back bioprinting with a $100,000 grant. Unlike other forms of bioprinting, the project being backed would eventually be able to print nearly anything by pulling the ingredients from thin air.

Imagine being able to print anything from tools and composite building materials to food and human tissues. Imagine being on Mars with the ability to replace any broken part, whether it’s a part of your spacesuit, your habitat, or your own body. We propose a technique that would allow just that. By printing 3D arrays of cells engineered to secrete the necessary materials, the abundant in situ resources of atmosphere and regolith become organic, inorganic, or organic-inorganic composite materials. Such materials include novel, biologically derived materials not previously possible to fabricate. –Lynn Rothschild

The process is envisioned working by gathering sunlight and CO2 by way of algae collectors to provide energy. Raw materials are gathered as well, in the most basic forms possible, forming the building blocks of printed objects. These materials are then built up in standard AM fashion into engineered cells which, in turn, build the object required.

Any benefits to the space program would certainly trickle down to civilian industries, possibly bringing about new breakthroughs in medical bioprinting. The process could also be used to build miniaturized organs for testing — replacing the use of animals — for the creation of bioengineered implants, and biofilms for testing new medicines.

Below you’ll find a video about NASA’s more traditional use of AM to build a rocket engine fuel injector.

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE