Optomec Launches LENS 450 Metal 3D Printer

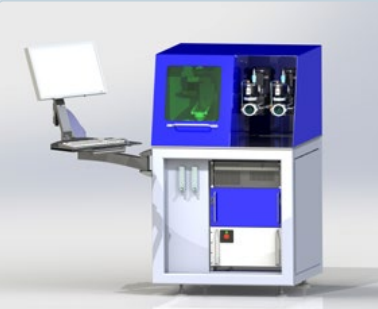

Optomec’s Lens 450 3D printer is meant to act as an entry level system into metal additive manufacturing. Courtesy of Optomec.

Latest News

June 13, 2013

As RAPID 2013 continued into day two, we discovered the LENS 450 metal additive manufacturing (AM) system; a new offering from Optomec. Described by the company as “low cost,” the new metal 3D printer uses the same technology as the LENS 850, but has a smaller footprint.

The LENS 450 has a 100 x 100 x 100 mm (3.9 x 3.9 x 3.9 in.) build envelope that is hermetically sealed for the operation of a 400W IPG fiber laser. It offers a deposition rate of up to 80 g/hour, positional accuracy of around .25 mm and a liner resolution of .025 mm.

To describe how Optomec’s LENS system operates, we’ll turn to the company’s description:

LENS systems utilize a high-power laser together with powdered metals to build fully dense structures directly from a 3-dimensional CAD solid model. The part is constructed layer by layer under the control of software that monitors a variety of parameters to ensure geometric and mechanical integrity. The LENS process is housed in a chamber which is purged with argon such that the oxygen level stays below 10 parts per million to ensure there is no impurity pick-up during deposition.

The LENS 450 can build objects employing a number of different materials, including stainless steel, cobalt chrome, titanium and superalloys. Completed objects can be further heat-treated, Hot-Isostatic-Pressed, machined, or finished in the same manner as parts built using traditional manufacturing methods. In addition to metal 3D printing, the system can perform near net shape builds and repairs.

The first system to be sent out will go to the Department of Mechanical Engineering and Material Science at the University of Pittsburgh, where it will be used in its new Advanced Manufacturing education program. With some concerns floating around that the US is actually falling behind in the AM race, the use of such a system at an institute of higher learning could be important for the future of 3D printing in the US.

“Re-establishing America’s global competitiveness is dependent upon a new generation of technicians and engineers trained in advanced manufacturing technologies,” said University of Pittsburgh professor C. Isaac Garcia. “The LENS 450 system is an excellent tool to conduct basic and applied research, and for training students on industry proven technology for metal Additive Manufacturing.”

Below you’ll find a video of the LENS 850-R in action, demonstrating Optomec’s process.

Source: Optomec

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE