MIT 3D Prints Bone

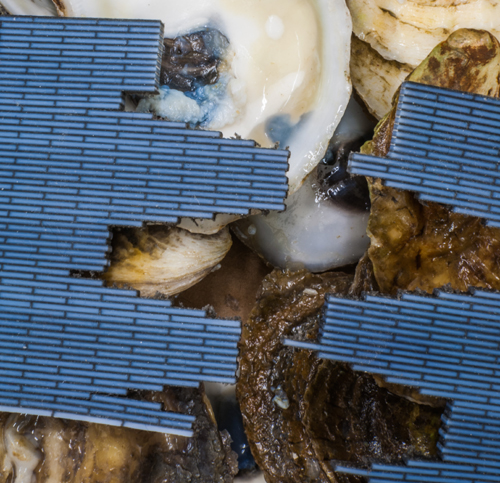

This photo shows the brick-and-mortar pattern of simulated bone and nacre against the backdrop of real nacre found in the inner shell of many molluscs. Courtesy of MIT.

Latest News

June 18, 2013

Syfy’s show Eureka aired an episode in which bio additive manufacturing (AM) systems printed out entire bodies to create clones of people. Of course, the show used the idea to perpetuate the old pod person trope of clones replacing the original people, but the technology isn’t entirely fictional. Bioprinting has been used to print ears, synthetic human tissue, and is being developed to produce vasculatory systems and organs.

Put together, those advances almost provide enough material to reproduce a human, minus the skeleton. Now, researchers at MIT have figured out a method to print synthetic bone using a mix of a soft polymer and a stiff polymer in a brick formation. The findings were reported in Advanced Functional Materials titled “Tough Composites Inspired by Mineralized Natural Materials: Computation, 3D printing, and Testing.”

“The geometric patterns we used in the synthetic materials are based on those seen in natural materials like bone or nacre, but also include new designs that do not exist in nature,” said associate professor Markus Buehler of the Department of Civil and Environmental Engineering. “As engineers we are no longer limited to the natural patterns. We can design our own, which may perform even better than the ones that already exist.”

The research resulted in three different synthetic composite materials. The first simulates the properties of bone, the second simulates the mineral calcite, and the last was developed with a diamond-like pattern to improve upon the basics provided by nature, providing a mechanism to further spread out any damage to the material. After building the composite materials, the researchers conducted tests to determine if they fractured in the same manner predicted by computer simulations.

“Most importantly, the experiments confirmed the computational prediction of the bonelike specimen exhibiting the largest fracture resistance,” said Leon Dimas, first author of the paper. “And we managed to manufacture a composite with a fracture resistance more than 20 times larger than its strongest constituent.”

MIT isn’t the only place research is being conducted on 3D printed bone. Below you’ll find a video from Washington State University about its project.

Source: MIT

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE