GE Prepares to Test the Potential of Additive Manufacturing

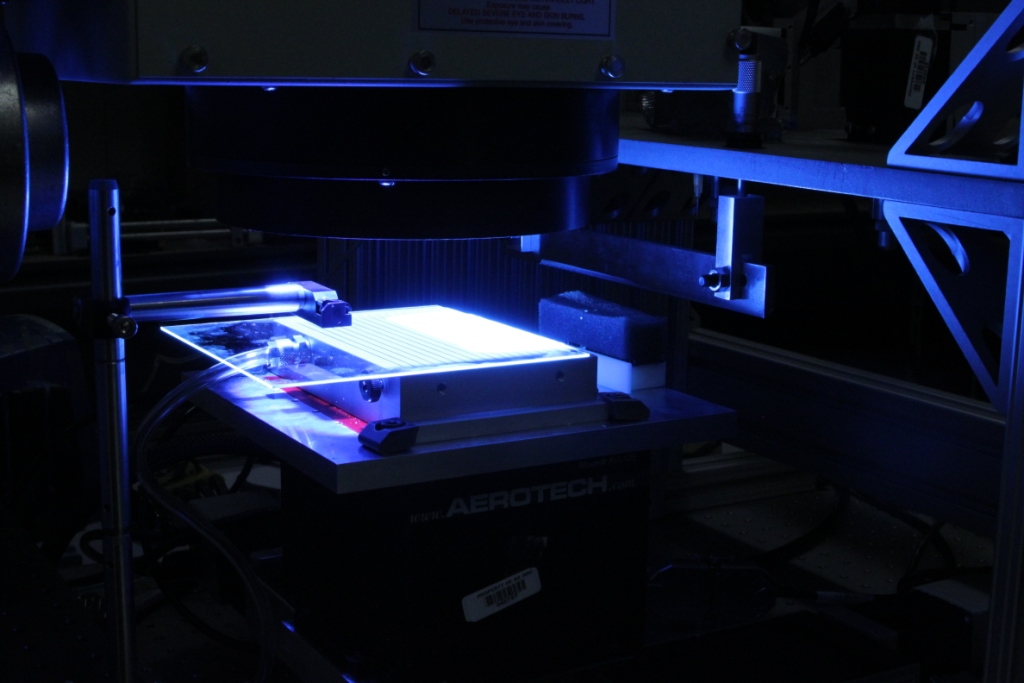

Along with its aerospace interests, GE is using UV 3D printing to design new ultrasound probes. Courtesy of GE.

May 2, 2013

By now it’s no secret that aerospace manufacturers are very interested in 3D printing. Additive manufacturing (AM) has begun to make its presence known at airshows, was already at work in the prototyping process and has become a key part of building a few, small aircraft and UAVs.

GE is just one company that has taken notice of AM and, late last year, made a significant investment in the technology when it acquired Morris Technologies, and its 3D printing service, Rapid Quality Manufacturing. Now GE is getting ready to flex its AM muscle with a large scale industrial test of 3D printing.

GE Aviation, in cooperation with Snecma, will be leveraging AM to build nozzles for its LEAP engine. The company intends to begin full production by early 2016 at the latest. Each LEAP engine requires 10 to 20 nozzles and GE will need to manufacture around 25,000 of the nozzles each year. That level of production is beyond the norm for AM. You can be sure other businesses will be keeping an eye on GE’s progress to see if 3D printing scales up as well as the company hopes.

GE will be using laser sintering techniques to build the nozzles, for the usual reasons AM-built parts are selected. Material loss is significantly reduced through additive methods, because most of a material doesn’t end up as scrap. AM also allows for more complex geometries than traditional manufacturing methods, and increasingly, is capable of creating multi-material parts in a way unique to the technology.

“As manufacturing becomes more advanced, we’re beginning to see laser technologies in manufacturing move from specialty applications to common tools used by manufacturing workers on the plant floor,” said Hongqiang Chen, who leads new developments for GE in laser technology. “New manufacturing employees will sort of be like Jedi Knights, wielding laser tools that cut, weld and scribe advanced metal and ceramic materials into parts.”

While AM is fantastic for aerospace, other GE divisions are also investigating how 3D printing can improve product design and production. The company has been experimenting with UV 3D printing to build ultrasound probes, and looking for ways to use the technology for wind turbines and designing new parts for use with natural gas.

Below you’ll find a short video featuring GE CEO Jeffrey Immelt discussing the potential of AM.

Sources: GE, MIT Technology Review

Subscribe to our FREE magazine, FREE email newsletters or both!

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DERelated Topics