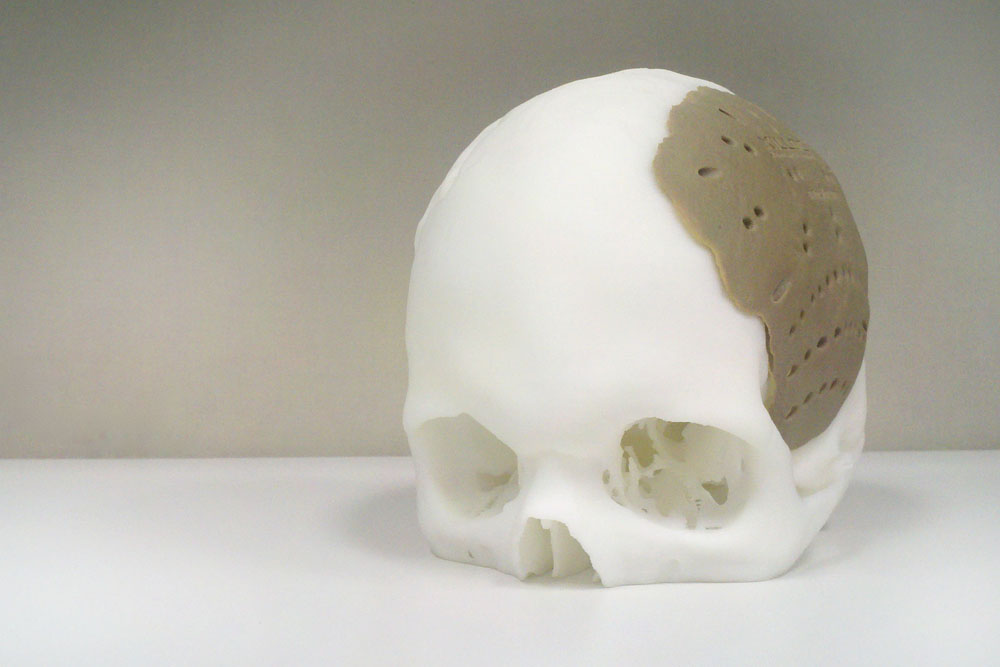

OPM’s OsteoFab process creates cranial impants using 3D printing. Courtesy of OPM.

March 8, 2013

In the course of my diligent efforts to keep you good people up to date on the state of additive manufacturing (AM), I come across many interesting news items. I’ll gather them up every so often and present them in a Rapid Ready Roundup (like this one). You can find the last Roundup here.

Let’s start today’s Roundup with a look at a new medical use for AM. Oxford Performance Materials (OPM) has received FDA approval for its OsteoFab biomedical process. OsteoFab uses an EOS P800 and PEKK material to build cranial implants. The implants can be used to repair damage and trauma to the skull, replacing missing bone and integrating with surrounding bone.

OPM’s process has already been in use overseas, but this marks the first time the FDA has given approval for AM-created implants to be used in humans in the US. OsteoFab can now be used to treat a variety of patients, including veterans who have suffered severe head trauma. Approval also opens the door for other uses of AM implants.

“If you can replace a bony void in someone’s head next to the brain, you have a pretty good platform for filling bony voids elsewhere,” said Scott DeFelice, president of OPM.

Moving on, 3D printing is becoming more readily available to the public, even for people who don’t own a 3D printer. Commercial enterprises such as Shapeways give anyone with a credit card the chance to own something built with AM. Now, a new startup named Dreambox is looking to make 3D printing even more accessible.

Dreambox is designing remote AM kiosks that take orders from the cloud and 3D print a selected or uploaded design. When the build is finished, the order is dropped into a storage drawer and the customer receives a text message with a code. Inputing the proper code allows the customer to open the drawer and retrieve their order.

“3D printing will enable every human on this planet to design, customize, and create products to solve problems — from the slightest household annoyance to global issues — and we’re here to fuel the revolution from the bottom up.” — Dreambox Team

Next, we recently covered a nifty little machine named the Lyman Filament Extruder II that makes inexpensive plastic filament from pellets. The Lyman, along with Filabot offer potential solutions to the expense of ordering plastic filament. These machines have been joined by the RecycleBot.

The RecycleBot (plans can be found at Thingiverse) spins plastic filament from plastic milk jugs. While the material isn’t perfect for producing plastic filament, it is a viable replacement for manufactured filament, according to Joshua Pearce, who led the project to create the RecycleBot at Michigan Technological University.

“Three billion people live in rural areas that have lots of plastic junk,” said Pearce. “They could use it to make useful consumer goods for themselves. Or imagine people living by a landfill in Brazil, recycling plastic and making useful products or even just ‘fair trade filament’ to sell.”

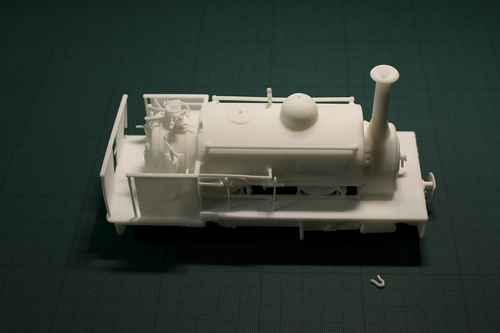

Finally, plenty of people enjoyed building model trains as a child, and many older folks continue to enjoy the hobby. Flexiscale is using AM to create model train kits with a greater amount of detail and accuracy than the mass-produced versions you find in stores. The company 3D scans trains and uses that data to build a digital model. From there the company either prints out the kit itself using a MakerBot system, or contacts a service bureau for more detailed prints.

“As a lifelong model railway person I’ve always wanted kits of specific things I couldn’t find,” writes founder Chris Thorpe on the Flexiscale blog. “Now thanks to 3D scanning and 3D printing, I can have them. Now that we’re investigating and using crowdsourcing and crowdfunding, others can have that experience too with kits they’ve always wanted.”

Below you’ll find a short video about the Dreambox.

Sources: Smartplanet, Flexiscale, Dreambox, Live Science

Subscribe to our FREE magazine, FREE email newsletters or both!

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DERelated Topics