4D Printing Touted as the Future of Manufacturing

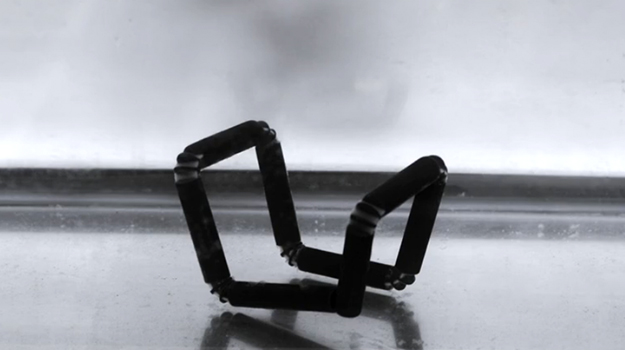

This structure formed itself from a chain of self-assembling material. Courtesy of MIT.

Latest News

March 6, 2013

Additive manufacturing (AM) is still at the stage where many people have no idea what the technology is about or what it can produce. More often than not, when I tell someone I write about 3D printing, I get a blank stare in response. Even when I describe the technology for those few that are interested enough to ask questions, I get the distinct impression that they either don’t believe what I’m saying, or think I’m exaggerating.

Imagine, then, the response that Skylar Tibbits must get when he talks about 4D printing, otherwise known as self-assembly. If people think I’m crazy when I talk about how AM can manufacture a new ear for someone or build a working prototype of a complex part in hours, I can only speculate on what they think when Tibbits starts explaining about parts that are capable of putting themselves together.

Tibbits looks at 4D printing as the future of manufacturing, and not just manufacturing small objects, but large construction projects, such as buildings. He says that current methods of manufacturing have become ever more complex, requiring more and more parts to go into one completed piece, at the cost of more time spent on construction. He asks the question, what if the parts could construct themselves?

The basic idea of self-assembly is that each part of whatever it is you’d like to build responds to programming based on what the part before it has done. So, if you want a square, the parts in a chain of 4D material base their bias on whether the part just before them has turned left or right (or not at all), before adjusting its own position to help form a square and passing that information on to the next part in the chain.

If this sounds similar to the manner in which natural organisms build structures, Tibbits has drawn inspiration from biological materials.

“I think there are a number of very interesting developments in science, engineering and design that are not only taking inspiration from nature — they are literally using nature — such as DNA origami (or self-assembly of DNA strands to build 2D and 3D shapes at the nano-scale), said Tibbits in a TED interview. “Biological processes are far more complex, efficient, precise, adaptive then nearly any manmade process or machine we have today, so it makes perfect sense to use biological processes for what they are good at, or manipulate specific variables within them to achieve something they could never have arrived at themselves.”

Even if the future is based on 4D printing, that doesn’t mean the end of the line for AM. 3D printing is being used to develop the technology and will continue to be an important part of the process in any self-constructed future.

Below you’ll find a couple of videos about 4D printing. The first is a TED talk by Tibbits, and the second shows a couple examples of self-assembly in action. Note that Tibbits is sitting on one of the finished pieces in the second video, which is as interesting a comment on the idea as the end result.

Source: TED

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE