Autodesk Stakes Claim to Bioprinting Frontier

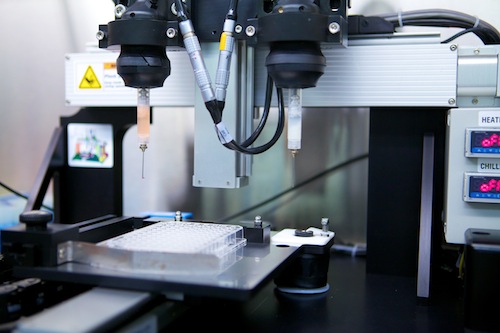

Autodesk is entering the world of 3D bioprinting, teaming up with Organovo to develop 3D design software that will work with the company’s NovoGen MMX bioprinter. Image Courtesy of Organovo

January 11, 2013

It may seem a bit sci-fi or even far-fetched to consider the brave new world of creating human tissue and organs as yet another design frontier, but to 3D CAD leader Autodesk, it’s a likely evolution.

Autodesk Research, and specifically a 14-person team known as the Bio/Nano/Programmable Matter group, has just announced a partnership with Organovo Holdings Inc., a manufacturer of three-dimensional human tissues for medical research and therapeutic applications (read our previous coverage of Organovo here), to create what both claim will be the first 3D design software for bioprinting.

Organovo’s 3D bioprinting technology is used to create living human tissues that are not only three-dimensional, but also architecturally correct and made entirely of living human cells. The resulting structures, which are output on Organovo’s NovoGen MMX bioprinter, are able to function like native human tissues, and company officials are touting their research and early prototypes as central to advancing medical research, drug discovery and development, and eventually, surgical therapies and transplantation.

So what can Autodesk bring to the table to advance this highly scientific and critically important area of research? Initially, the company’s expertise and background in 3D design software, particularly in the areas of usability and automation can help streamline what to date is a largely manual process.

“The way engineers and scientists work today in 3D bioprinting is a highly manual process so it’s a natural fit for design software to streamline those processes in much the same way we do in other parts of industry,” notes Carlos Olguin, leader of Autodesk’s Bio/Nano/Programmable Matter group. Initially, Autodesk plans to do a “one-to-one lateral map” of the technologies it delivers around manufacturing software (things like 3D CAD and simulation capabilities, for example) and tune them to the process of 3D bioprinting. Down the road and as Autodesk develops expertise in this domain, Olguin says the company is interested in creating new types of programs and capabilities that reflect the specific nature of the bioprinted substrates.

Olguin says dipping its toes (or maybe even diving into) the waters of biotechnology is a natural extension of Autodesk’s design heritage. “We think of life as a new design space for us,” he explains. “We spent the last 30 years looking at creating tools to design inert objects, now we’re ready to move on to transformative design where things have their own life.”

Keith Murphy, chairman and CEO of Organovo sees the Autodesk collaboration as a way to potentially open up bioprinting for a broader group of users. “The relationship will lead to advances in bioprinting, including both greater flexibility and throughput internally, and the potential long-term ability for customers to design their own 3D tissues for production by Organovo,” he said, in a prepared statement as part of a press release announcing the relationship.

Olguin says the first fruits of the partnership might be available in the next year or so.

To see a video of how Organovo’s bioprinting process and technology works, click here.

Subscribe to our FREE magazine, FREE email newsletters or both!

About the Author

Beth Stackpole is a contributing editor to Digital Engineering. Send e-mail about this article to [email protected].

Follow DERelated Topics