University of Illinois Scientists Create Bio-Bots with 3D Printing

University of Illinois at Urbana-Champaign have used 3D printing to create biomechanical robots. Courtesy of University of Illinois.

Latest News

November 16, 2012

Scientists are experimenting non-stop with additive manufacturing (AM). Moving into realms far beyond rapid prototyping, AM offers researchers the flexibility to build whatever tools or experimental objects are required. This does, of course, require some trial and error, but each successful step makes using AM technology that much more attractive.

Researchers at the University of Illinois at Urbana-Champaign are using 3D printing to create what they call “bio bots.” Generally, when people think of robots, they envision machines built from materials such as hard plastic or metals. Those kinds of materials are hardly ideal for certain applications, however, such as diving into the bloodstream of a patient.

“As engineers, we’ve always built things with hard materials, materials that are very predictable, said Rashid Bashir, an Abel Bliss Professor of Engineering. Yet there are a lot of applications where nature solves a problem in such an elegant way. Can we replicate some of that if we can understand how to put things together with cells?”

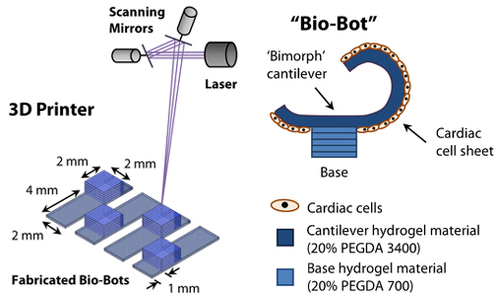

Bashir’s team used a HeCd laser and galvanometer scanning mirrors to build a stereolithography 3D printer. As one would expect with AM, each bot was built a layer at a time. The first layer to be completed consisted of soft cantilever hyrdrogel, followed by a more rigid hydrogel precursor solution. Next came the biological “motor” for the bots. From the published research paper:

Cardiomyocytes derived from neonatal rat hearts were extracted and seeded onto the cantilevers. The cardiomyocytes attached to the cantilevers, increased in size, and exhibited spontaneous contractile activity. Over several days, they produced a confluent culture and formed a cardiac cell sheet that contracted in synchrony.

The end result was a series of bio bots measuring between 5 to 10 mm. The slow beating of the bio motor allowed the bots to move forward with at a max speed of

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE