Organovo and Modern Meadow Develop Bioprinting for the Future

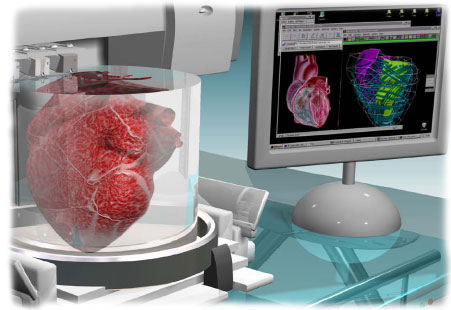

Bioprinting may well provide new organs in the near future. Courtesy of Medical University of South Carolina.

Latest News

November 2, 2012

Medical applications for additive manufacturing (AM) are many and varied. Early adopters have already begun using the technology to create prosthetics of all sorts, and it should go without saying that AM can produce nearly any custom part needed for medical use or health care in general. While the advances brought about in those areas via AM are fantastic, the future holds more potential for medical AM in form of bioprinting.

Rapid Ready has touched on bioprinting before, but the technology is advancing at a rapid pace, and is expanding what might be considered obvious usage. I also want to consider the financial aspects of the field. No matter how promising, this technology won’t get off the ground without the cash to back it.

If you are looking for a name to follow for developing trends in bioprinting, you could do worse than keeping any eye on Andras Forgacs. An ex-investment banker, consultant and venture capitalist, Forgacs is the co-founded of two different firms that are investigating the opportunities offered by bioprinting.

The more traditional (if such a word is even relevant, here) company is Organovo, which is developing printed skin, organs and other such “standard” medical uses for bioprinting. The other company is named Modern Meadow, and it is researching the use of bioprinting to create meat. As in, “It’s what’s for dinner.”

Organovo wants to be the future provider of bioprinted organs, but the operative word in that sentence is “future.” The technology simply isn’t ready for those sorts of challenges, at least yet. Rather than throw money into a research hole in hopes of a speedy breakthrough, the company has set forth a less ambitious plan that could provide the stream of capital required until bioprinting is ready for operating rooms.

The company believes it will be able to produce 3D printed human tissue in reasonable quantities in the near future. This tissue could be sold to research firms for testing purposes. In place of animal testing, any work that can be completed simply by observing how human tissue reacts to a project, researchers could order tissue from Organovo.

Modern Meadow is dedicated to providing an alternative source for meat production. One serious obstacle to this sort of enterprise doesn’t even involve technology, rather it is perception. My wife’s reaction to the idea of eating a 3D printed steak was, “yuck.” I rather suspect that is going to be most people’s initial reaction. Overcoming that particle problem will require time and a serious marketing campaign.

Modern Meadow is aware of the potential pitfall, and has elected to fund further study, and possibly to bankroll marketing, by investigating the use of bioprinting to create artificial leather. Unlike the “pleather” you see now, this stuff would have all the characteristics you’d expect from the material if it came from a cow instead of an AM system.

According to Forgacs, the company will be able to produce a 2 cm wide strip of leather by the end of the year, and are on course to enter full production within five years. Tell your vegan friends (you know who they are)! Both plans have the potential to provide enough financial gains to keep Forgac’s operations in business until technology catches up with idea.

Below you’ll find a video featuring Andras Forgacs.

Sources: Organovo, Modern Meadow

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

John NewmanJohn Newman is a Digital Engineering contributor who focuses on 3D printing. Contact him via [email protected] and read his posts on Rapid Ready Technology.

Follow DE